Machine Integration

As manufacturers move towards the perceived ideal of Industry 4.0, integration of new and legacy machines and systems becomes all the more important.

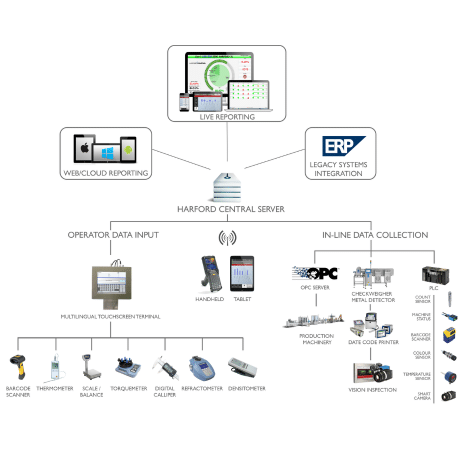

Harford Machine Integration enables efficient data exchange and synchronisation between machines, streamlining operations for optimal performance. Features such as auto result capture and connectivity with HPLC, densitometers, in-line check-weighers etc., enhance data accuracy and analysis, resulting in improved decision-making capabilities.

Machine Integration – Reducing Downtime & Increasing Productivity

Machine integration enables seamless coordination and communication across machines on the production line, improving efficiency, reducing changeover times and increasing overall productivity.

Machine Integration = Higher Outputs, Less Downtime & Improved Data Accuracy

Machine integration provides numerous advantages to production operations. It increases efficiency by enabling seamless coordination and communication between machines, resulting in higher output and less downtime. The connection also assures optimal performance by offering streamlined operations through effective data interchange and synchronisation.

Automation with date coders, on-line scanners, in-line check-weighers, vision systems and PLCs help to show a more holistic picture of overall production performance.

Machine Integration Solutions for FMCG, Food & Drink, & Pharma

Efficient machine integration is essential for businesses in industries where production processes involve multiple machines, companies in FMCG, Food and Beverage, Health and Beauty, Pharmaceutical and Chemicals all experience real benefits.

Seamless coordination

Smooth communication and coordination among production line machines.

Enhanced data exchange

Efficient data sharing and synchronisation between machines for improved productivity.

Auto result capture

Automated capturing of results, reducing manual effort and ensuring accuracy.

HPLC Anton Parr connectivity

Integration for seamless data exchange and analysis, ensuring precise measurements and quality control.

Why Work with Harford Control?

The continuous development of our performance improvement systems for more than half a century keeps us at the leading edge of real time factory floor MES technology. No other single company has created such an impressively integrated set of production modules which so seamlessly work together to form the most comprehensive picture of factory performance.

Harford Control ensures seamless machine integration, enhancing productivity and optimising workflows. As a client-centric partner, we tailor solutions to meet the needs of FMCG, food and beverage, health and beauty, pharmaceutical and chemical industries.

Who We Have Helped

FAQs

-

What is machine integration in manufacturing?

Machine integration involves connecting various machines and equipment within a production line to function harmoniously. This integration facilitates real-time data exchange, process automation, and heightened efficiency in manufacturing operations.

-

What are the benefits of machine integration?

Machine integration optimizes production workflows, minimizes manual interventions, enhances data precision, and boosts overall productivity. It empowers informed decision-making through access to instant data insights.

-

Which industries benefit from machine integration systems?

Industries spanning automotive, electronics, food and beverage, pharmaceuticals, and more reap rewards from machine integration. Sectors with intricate production processes can elevate efficiency with integrated machinery.

-

How does machine integration improve data collection?

Machine integration automates data collection from diverse sources, eliminating errors from manual input. Accurate, real-time data collection aids thorough analysis and informed decision-making.

-

How does machine integration improve manufacturing compliance?

Machine integration ensures that processes are standardized and monitored, reducing the potential for deviations from regulatory requirements. By automating compliance checks and documentation, it enhances consistency and conformity to industry standards.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.