Statistical Process Control (SPC)

In 1921 Dr Walter Shewhart, working for Bell Laboratories, USA, first developed the use of the control chart which lead to SPC. He is seen as the Father of Statistical Process Control (SPC).

Within the Harford system we use SPC to get the very best from Average Quantity Law for our clients. Users also have the opportunity to apply the Harford SPC programme to other measurements where controllable variation exists, such as direct collection of data from torque meters, thermometers, etc.

Achieve Optimal Fill Levels & Minimise Waste with Our SPC Solutions

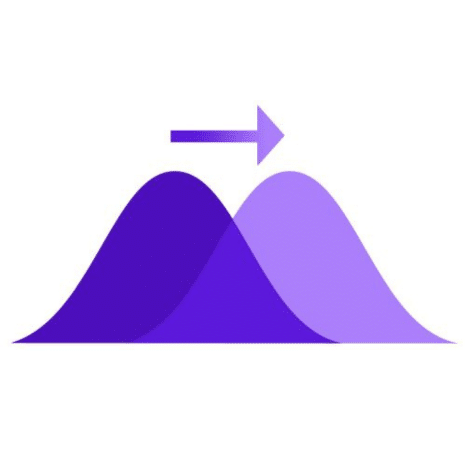

Statistical Process Control and Process Capability are very much interrelated, in that SPC can only be applied to a controllable process where the performance is predicable. In other words, the process must be brought under control before SPC can be applied. Once under control, SPC can be used to measure the degree of variation.

From this, the Harford system then automatically calculates the process capability and sets optimum control limits. This achieves three things:

- compliance with legal requirements,

- reduction of overfill and this leads to

- fewer process adjustments.

A few decades ago, Quality and Technical Managers carried out Process Capability Studies on their production lines, to determine the optimal setting of the most appropriate control limits. SPC would be an integrated part of such analyses.

This is normally carried out on paper, with a pocket calculator, from which the best settings would be chosen. This required the technical team to have an in-depth understanding of SPC and process capability, such that they knew and understood the calculations to be made for the setting of such limits. As each product/production line would be likely to have its own degree of controllable variation, this would need to be carried out multiple times.

Improve Production Performance & Optimise Production Outcomes

With the growing trend of Supermarket own-label, this meant that many manufacturers moved from a relatively small number of products to often very large product portfolios. Therefore, the prospect of carrying out manual SPC analysis for each combination became untenable.

Harford SPC, used within our advanced automated control system, ensures the greatest stability, fewest number of adjustments, and optimal fill levels for each product/production line combination. By leveraging our cutting-edge SPC solution, manufacturers achieve enhanced process control, reduced variations, improved efficiency, and precise adherence to product specifications.

Process Data, Control Charts & Trend Analysis Tools

Harford SPC can also be used for other performance control measures in areas such as:

- Temperature (°C, °F)

- Pressure (PSI)

- The torque needed to tighten caps on bottles (Nm, Ncm, n.lb)

- The length of particular product (cm, m, inches or feet)

They provide visual representations of process data, control charts, and trend analysis tools. Real-time alerts and notifications allow for proactive quality management, ensuring process stability and continuous improvement.

SPC Solutions for FMCG, Health & Beauty, Food & Pharma Companies

Without the Harford Average Quantity Control system, it was common to set arbitrary control limits for filling machines based upon ‘what Quality or Technical would like them to be, e.g. plus or minus 2 grams’.

This is why we developed the Harford system to carry out automatic SPC and Process Capability analyses and to thereby set the most appropriate Target and Control Limits for each product/production line combination, thereby achieving optimum fill levels with minimal ‘giveaway’ and fewer process adjustments.

Set Target Value

Establish precise target values for each product/production line based upon process capability.

Density Lab Check

Ensure accurate measurements and quality control through density testing.

Adjustment Resolution

Fine-tune processes with minimum SPC adjustment steps for better control.

Various Parameter Types

Monitor and analyse multiple parameters like product, material, and machine.

Trend & Advice

Receive real-time trend analysis and actionable advice for process optimisation.

Why Partner with Harford Control for SPC?

With over 50 years’ experience, the Harford team has been dedicated to developing and implementing Statistical Process Control (SPC) solutions. We specialise in automatic SPC and Process capability analyses, enabling us to set optimal Target and Control Limits for every product/production line combination.

Our unique approach emphasises continuous improvement, tailoring our SPC solutions to meet the specific requirements of our clients in the FMCG, Food & Beverage, Health & Beauty, Pharmaceutical and Chemical manufacturing industries.

All our developments are targeted to make routine tasks as easy and meaningful as possible for our clients.

Who We Have Helped

FAQs

-

What is SPC?

Statistical Process Control (SPC) is a methodology that uses statistical techniques to monitor and control manufacturing processes. It involves analysing process data in real-time to detect variations, identify root causes, and take corrective actions to maintain process stability and product quality.

-

What are the benefits of implementing SPC?

Implementing SPC offers several benefits. It helps to identify process variations, reduce defects, and improve overall product quality. SPC enables proactive monitoring and early detection of process deviations, preventing non-conforming products and minimizing waste. It also provides insights into process capability and helps in making data-driven decisions for process optimization.

-

How does SPC contribute to process improvement?

SPC contributes to process improvement by providing real-time data analysis and visualization. It helps identify common and special cause variations, allowing for targeted improvement actions. SPC facilitates continuous monitoring of process performance, enabling organizations to implement corrective measures promptly, reduce variability, and achieve consistent product quality.

-

What are the key elements of SPC?

The key elements of SPC include the identification of critical process parameters, data collection and analysis, control charting, setting control limits, and taking corrective actions based on statistical analysis. SPC emphasizes process stability, measurement system accuracy, and the reduction of common cause variation to ensure consistent and predictable process performance.

-

How can SPC improve overall productivity?

SPC improves overall productivity by reducing process variability and minimizing defects. By implementing SPC, organizations can identify and eliminate process inefficiencies, resulting in improved process yield, reduced rework or scrap, and increased throughput. SPC also enables process optimization, leading to enhanced resource utilization and operational efficiency.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.