Raw Material & Labour Wastage Monitoring

Harford Raw Material & Labour Wastage Monitoring Solutions assist manufacturers in tracking, analysing and optimising material usage and labour resources, resulting in reduced wastage, improved operational performance and cost savings.

Raw Materials & Labour Wastage Monitoring

Harford raw materials and labour wastage monitoring solutions empower manufacturers to track, analyse, and optimise material usage and labour resources, leading to reduced wastage, improved operational performance and cost savings. These solutions enable root cause investigation of downtime and wastage, revealing inefficiencies, bottlenecks, and areas for improvement. The benefits encompass increased production output, reduced costs and enhanced sustainability practices.

Enhanced Visibility and Data-Driven Insights

By implementing raw materials and labour wastage/monitoring solutions, companies can identify and reduce instances of waste, leading to significant transformation cost savings. These solutions enable better resource allocation, minimise overconsumption of materials, and optimise labour utilisation. Enhanced visibility and data-driven insights enable proactive decision-making, improving overall efficiency and productivity.

Effective Problem-Solving and Prevention Measures

Harford Control’s raw materials and labour wastage/monitoring solutions offer real-time data capture, monitoring and analysis of material usage and labour resources. They enable investigation into the root cause of wastage, allowing for effective problem-solving and prevention measures. These solutions seamlessly integrate with existing systems, utilise advanced tracking technologies, and identify areas of wastage to enhance overall manufacturing performance.

Materials & Labour Wastage Monitoring for A Range of Industries

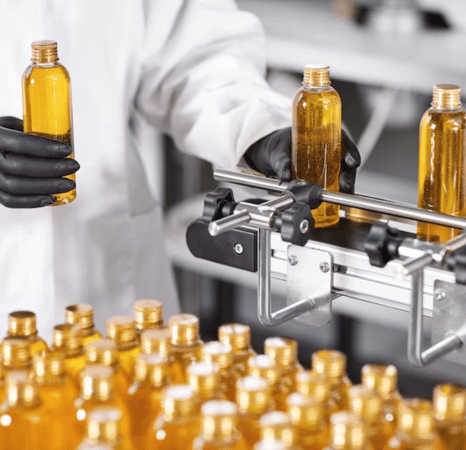

In industries such as FMCG, Food & Beverage, Heath & Beauty, Pharmaceutical and chemical, efficient utilisation of raw materials and labour is vital for profitability and competitiveness. Harford Control raw materials and labour wastage monitoring solutions address these industries’ specific challenges by providing accurate monitoring of raw material consumption and labour performance, helping companies drive waste reduction, improve production efficiency and achieve higher levels of operational excellence.

Waste Minimisation

Identify and minimise wastage throughout the manufacturing process to enhance operational efficiency and cost-effectiveness.

Raw Materials Consumption Tracking

Efficiently track and monitor the consumption of components, materials, and finished products to optimise resource utilisation.

Poor Performing Material Identification

Identify and address poorly performing materials to enhance overall product quality.

Labour Allocation Tracking

Ensure the appropriate allocation of labour to each production line for optimised efficiency.

Labour Performance Monitoring

Continuously monitor and assess labour performance to drive productivity and accountability.

Why Work with Harford Control?

Over several decades, Harford Control has worked tirelessly with a wide range of factories across five continents to help optimise their production performance.

With the Harford Manufacturing Execution System (MES) tailored to individual needs, it becomes easier to reduce errors, find the hidden wastage and consequently become more efficient, whilst continuing to deliver consistently high quality products, thereby making each business more profitable and sustainable.

Most manufacturers are facing ever increasing input and transformation costs with few opportunities to increase the output price to their customers (High Street Multiples).

This encourages manufacturers to look more deeply into their production processes to find the hidden costs, eliminate wastage and thereby improve efficiency without compromising quality.

The problem of rising input costs and fixed output costs is nothing new and will not end. Therefore performance improvement to drive down transformation costs must be continuous for the business to sustain its market position and avoid losing its place on supermarket shelves to the competition.

Who We Have Helped

FAQs

-

How can raw materials and labour wastage be monitored?

Raw materials and labour wastage can be monitored through various methods. These may include tracking material consumption, conducting regular audits, implementing waste reduction strategies, and analysing production data. Utilizing advanced manufacturing systems and technologies, such as MES (Manufacturing Execution Systems), can provide real-time visibility into material usage and labour performance, enabling effective monitoring and control.

-

What are the main causes of raw materials and labour wastage?

Raw materials and labour wastage can have several causes, such as inefficient processes, poor training, inadequate quality control, and ineffective inventory management. Inaccurate measurements, equipment breakdowns, and lack of standardization can also contribute to wastage. By identifying the root causes and implementing corrective measures, manufacturers can minimize wastage, optimize resource utilization, and improve overall operational efficiency.

-

How does monitoring raw materials and labour wastage benefit manufacturers?

Monitoring raw materials and labour wastage offers significant benefits for manufacturers. It helps identify inefficiencies, cost-saving opportunities, and areas for process improvement. By reducing wastage, manufacturers can minimize material and labour costs, improve product quality and consistency, enhance productivity, and maintain better control over production processes. Ultimately, it leads to increased profitability and competitiveness in the market.

-

How can manufacturers reduce raw materials and labour wastage?

Manufacturers can reduce raw materials and labour wastage by implementing waste reduction strategies and process improvements. These may involve optimizing inventory management, implementing lean manufacturing practices, conducting regular training and skill development programs, improving quality control processes, and utilizing data-driven insights for continuous improvement. By fostering a culture of waste reduction, manufacturers can enhance efficiency, reduce costs, and increase sustainability.

-

How can manufacturers improve labour monitoring to reduce wastage?

Manufacturers can improve labour monitoring to reduce wastage by implementing effective tracking and performance measurement systems. This may involve using time-tracking tools, performance metrics, and real-time monitoring technologies. By accurately capturing and analysing labour data, manufacturers can identify areas of improvement, streamline workflows, optimize workforce allocation, and reduce unnecessary labour costs, leading to increased productivity and reduced wastage.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.