Process Integration to Streamline Production

As reduction of wastage becomes increasingly important, the pressure to achieve more in production operations naturally increases proportionately. Every successful manufacturer is now trying to squeeze the maximum from raw materials to achieve optimum output of finished products.

Harford Process Integration covers the quality and quantity of goods inwards and tracks the products through the various processes to final packed product and despatch, helping you to streamline your production processes.

Production Integration Solutions – Minimise Wastage & Enhanced Efficiency, whilst Sustaining High Quality Standards

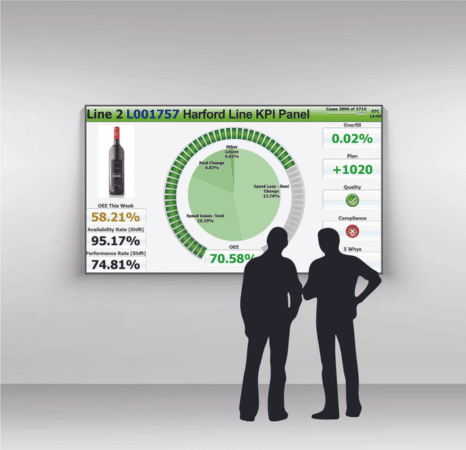

Using Harford Process Integration to streamline your production throughput, involves monitoring the entire journey of raw materials, from the initial stage, to the final processing and packaging. It ensures the efficient preparation of bulk products for packaging in the designated hall and seamless integration with existing machinery. Our solution provides real-time visibility into performance and quality metrics, thereby reducing wastage, optimising efficiency and sustaining high quality standards.

Real-Time Visibility of Manufacturing Performance and Quality Metrics

Our end-to-end real-time traceability ensures transparency throughout the production process, enabling rapid decision making based upon root cause analysis, rather than quick fixes or knee-jerk responses. The benefit of fixing problems permanently as they arise cannot be overstated, as it minimises lost production through frequent unscheduled stoppages and the manufacture of defects.

Production/Process Integration Systems for a Range of Industries

The target of our developments has been driven by the nature of production and process integration, the minimisation of variation and the crucial need across all manufacturing industries, to reduce wastage and improve efficiency, whilst upholding the highest quality standards, but most of all, to integrate production equipment, data and workers. Sometimes the importance of workers is underestimated, but it is only through the involvement of engaged and connected workers that quantifiable and sustainable benefits can be achieved.

Process Tracking

Track each step of the process, i.e. temperature, sugar levels, etc. to ensure optimal conditions.

Material Process Monitoring

Monitor the process of raw materials from start to finish.

Preparation for Packaging

Prepare the bulk products for packaging in the designated hall.

Automated Sampling

Samples are normally taken (automated wherever possible) at each production step for Quality Assurance and traceability.

Machinery Integration

Seamlessly integrate with existing machinery, wherever possible, for streamlined operations.

Why Choose Harford Control for Process Integration?

Harford Control specialises in providing real-time actionable information tailored to the unique needs of each manufacturer, but from standardised resources. Our expertise in process tracking, material journey monitoring and automated sampling ensures seamless process integration and data flow across different stages of the manufacturing process.

It almost goes without mention that the results to all recorded actions are instantly displayed for all relevant personnel to see current production status.

With over half a century of continuous development in performance improvement systems, we remain at the forefront of real-time factory floor MES technology. By actively listening to our clients’ needs, we continuously enhance and refine our process integration solutions to meet their evolving requirements.

Who We Have Helped

FAQs

-

How does process integration contribute to yield optimisation?

Process integration aligns different stages of production, minimising disruptions and optimising material flow. This synergy reduces waste, enhances efficiency, and ultimately boosts yield by creating a more streamlined and controlled manufacturing process. Effective integration ensures that every step contributes to a cohesive and productive whole, leading to improved yield rates.

-

What role does data exchange play in process integration for yield optimisation?

Data exchange between different manufacturing phases ensures seamless communication and synchronisation. Real-time data sharing enables proactive adjustments, quick decision-making, and the identification of areas for yield improvement. With integrated systems, data becomes a powerful tool for optimising yields as it provides comprehensive insights into each stage of production.

-

Can process integration improve overall production efficiency and yield?

Definitely, process integration eliminates bottlenecks and inefficiencies caused by disjointed operations. By creating a holistic production process, it maximises equipment utilisation, minimises downtime, and ultimately enhances yield rates. A synchronised and optimised production environment ensures that resources are utilised efficiently, contributing to higher yields.

-

How does process integration impact quality control and yield optimisation?

Process integration enhances quality control by standardising procedures and facilitating real-time data monitoring. This prevents defects, reduces rework, and maintains consistent product quality, thereby positively impacting yield optimisation. Quality assurance becomes an integral part of the integrated process, ensuring that yield is optimised without compromising product integrity.

-

Can process integration address yield variations across different production lines?

Yes, process integration allows for standardised practices across multiple lines. This minimises yield discrepancies by ensuring uniform processes, materials, and quality checks, leading to balanced and optimised yields. Regardless of the production line, integration ensures that best practices are applied consistently, leading to improved yield performance.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.