Centrelining

Centrelining, sometimes called Run-to-Target, seeks to drive optimal quality output by ensuring that the production machinery is set up to the previously agreed standards, to guarantee a consistent operational process through each production run.

Centrelining – Maximise Efficiency & Promote Product Standardisation

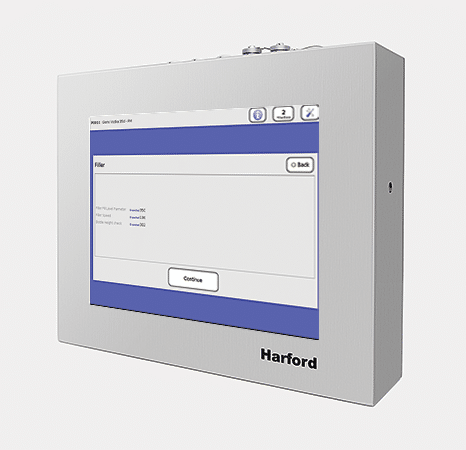

Harford Centrelining empowers manufacturers to optimise production processes, achieve consistent product quality and drive operational excellence. By establishing line-specific default parameters and adapting to changes through the implementation of appropriate training for operational personnel, Centrelining enables manufacturers to maximise efficiency, reduce setup time and promote standardisation. It ensures that production operations are finely tuned to deliver optimal performance and meet the evolving demands of the market.

Enhancing Production Efficiency & Manufacturing Performance

Harford Centrelining incorporates line-specific default parameters for each machine/product combination. By running a set of parameters, we identify the optimal configuration, which we set as the default. Operators have the flexibility to adjust parameters for special materials or product variations, and effortlessly transition back to the default settings for regular materials/production runs. This ensures a smooth adaptation to specific raw materials, ultimately achieving optimally efficient product changeovers on each production line.

Achieving Manufacturing & Operational Efficiency

We have seen many production situations where Centrelining has not been in evidence and not even understood. Consequently, consistently high quality from one production run to another (of the same product) becomes virtually impossible, or dependent upon luck and even guesswork.

To Centreline a process, it is generally accepted that the following four steps must be followed:

- Identify the important factors or variables.

- Determine the best settings and ranges for all important variables, by product, especially where multiple products are produced on the same line.

- Determine the extent to which these variables affect the process and product consistency.

- Ensure that the standardised settings are always used during production set-up and respected during each production run.

From the above four points, it becomes obvious that consistently effective Centrelining cannot be achieved through the setting of appropriate product variables alone. The operators must also be seen as an integrated part of Centrelining and trained accordingly.

Centrelining Systems for FMCG, Food & Drink, Health & Pharma Companies

Centrelining is especially vital in industries such as FMCG, Food & Beverage, Heath & Beauty, Pharmaceutical and Chemical, where consistent product quality and efficient production processes are critical. Implementing Centrelining enhances operational efficiency, drives standardisation, and establishes a foundation for continuous improvement. This empowers industries to achieve transformation cost savings, improve competitiveness, and maintain consistent product quality.

Default Parameter Optimisation

Line-specific default parameters for optimal performance.

Centrelining for Improved Results

Standardising to ensure product and efficiency consistency and minimise defects.

Adaptability to Changing Factors

Handling product variations, different materials, and machine requirements.

Seamless Adaptation

Smoothly transition from default settings to accommodate specific raw materials, then auto reset to default.

Maximising Line Efficiency

Achieving the best efficiency from the production line consistently across different production runs.

Why Work with Harford Control?

The continuous development of our performance improvement systems over the past half-century has positioned us at the forefront of real-time factory floor MES technology. Harford Centerlining integrates line-specific default parameters, customised to each machine’s requirements, and through the implementation of appropriate training, ensures unrivalled performance and efficiency. As a customer-centric partner, we specialize in tailoring solutions to cater for the unique needs of industries such as FMCG, Food and Beverage, Health and Beauty, Pharmaceutical, and Chemical.

We have financed a lot of research and work to achieve the highest standards within all our integrated and stand-alone software programmes. Centrelining is no exception. Without commitment to a reproducible reference standard and appropriate product set up, product changeover times are needlessly extended, and efficiency can be severely compromised, as operators and engineers struggle to ‘get it right’.

Operators must be trained (and retrained, especially with staff changes) to appreciate the need for consistently high quality, to understand what ‘Good’ looks like and engage fully to the extent that they take pride in ‘ownership of the line’ and in the consistency of products produced. They must also resist the temptation to tweak ‘settings’ whilst the line is already producing ‘in spec’ products and to realise that their absolute commitment to Centrelining makes their lives easier and their ‘lines’ more efficient. In doing so, they begin to realise the benefits of a truly ‘Connected Worker’.

Who We Have Helped

FAQs

-

What is centrelining in manufacturing?

Centrelining is a systematic approach to optimise the performance of manufacturing processes by identifying and establishing the optimal operating conditions. It involves setting and aligning key process parameters to achieve consistent and optimal output. Centrelining ensures that processes are running at their most efficient and effective levels.

-

Why is centrelining important in manufacturing?

Centrelining is important in manufacturing because it helps improve product quality, increase productivity, and reduce waste and variation. By setting optimal process parameters, it ensures consistent and reliable production, minimizing defects and rework. Centrelining also facilitates troubleshooting and problem-solving by providing a baseline for comparison and analysis.

-

How does centrelining work?

Centrelining involves collecting and analysing data to identify the ideal or “centred” values for key process parameters. These parameters can include temperature, pressure, speed, or other variables that impact product quality and performance. By adjusting the process settings to align with the centred values, manufacturers can optimize their operations and achieve desired outcomes.

-

What are the benefits of implementing centrelining?

Implementing centrelining brings several benefits to manufacturing processes. It improves process efficiency, reducing cycle times and increasing throughput. Centrelining also enhances product consistency, reducing variation and defects. It enables proactive maintenance and troubleshooting by identifying process deviations. Ultimately, centrelining leads to improved productivity, reduced costs, and enhanced customer satisfaction.

-

How does centrelining support lean manufacturing practices?

Centrelining aligns with lean manufacturing principles by eliminating waste, reducing variation, and optimizing processes. It helps identify and eliminate non-value-added activities, ensuring that resources are utilized efficiently. Centrelining also promotes standardization and continuous improvement, both of which are key tenets of lean manufacturing methodologies.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.