Materials Utilisation

For decades, utilisation of raw materials in FMCG has been sub-optimal for two main reasons. Raw materials were relatively cheap and selling prices were high. The consequential profits have encouraged wastefulness. During the same period, profit margins have come under increasing pressure due to increases in raw material costs and conversion costs, such as labour and energy resources, pushing against fixed selling prices and long term contracts with retailers.

Harford Material Consumption Solutions assist manufacturers in effectively tracking and monitoring the consumption of components, materials and finished products to enhance material efficiency in manufacturing processes.

Quantify, Track & Trace Materials Usage

Among the most disciplined and determined manufacturers with a total commitment to continuous improvement, there is now a ‘volte face’, whereby these producers see every £ as a prisoner! They are systematically and continuously clamping down on rework, rejects, overfills and general wastage, together with improving efficiency at every opportunity.

This is where Harford can really help in ensuring ‘right first time’ with the virtual elimination of rejects and rework through unique combinations of our software and hardware. Raw materials misuse, usage and optimisation is now under the spotlight, and brought sharply into focus by Harford as a key contributor to sustained performance improvement.

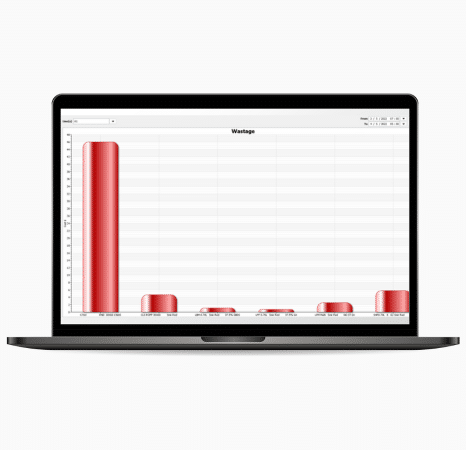

Minimise Wastage, Reduce Manufacturing Costs and Improve Efficiency

Deploying material consumption solutions brings numerous benefits to manufacturing companies. By efficiently tracking and monitoring the consumption of components, materials and finished products, businesses can identify poorly performing materials, minimise wastage, eliminate bottlenecks and reduce transformation costs. Efficient material consumption leads to enhanced productivity, streamlined processes, and improved manufacturing cycle times. Reducing material waste also contributes to sustainability goals, promotes environmental responsibility, and enhances each company’s reputation as a socially conscious organisation.

Monitoring & Managing Material Consumption

Material consumption solutions also help manufacturers control the material required to manufacture products. Through advanced inventory management, accurate forecasting, and waste reduction strategies, manufacturers can optimise material utilisation and minimise excess usage.

By precisely controlling material consumption, factories can eliminate shortages, whilst minimising the risk of overstocking and old stock going ‘out of date’ before use. Another major benefit is that effective materials control combines the benefits of JIT (Just in Time) with FIFO (First In, First Out).

Material Consumption Solutions for A Range of Industries

Material consumption solutions are vital across various industries, enabling companies to maximise resource utilisation, reduce waste, and improve profitability. From food and beverage to consumer goods, efficient material consumption helps manufacturers identify poorly performing materials, minimise material wastage and reduce transformation costs.

By adopting material consumption solutions, businesses can also track and trace material usage through batch labelling and more easily investigate the root cause of product recalls.

Raw Materials Consumption

Efficiently Track and Monitor the consumption of components, materials and finished products.

Waste Minimisation

Identify and Minimise Wastage throughout the manufacturing process.

Poor Performing Material Identification

Identify poorly performing materials to improve product quality.

Material Tracking and Traceability

Track and Trace material usage. JIT and FIFO.

Recall Root Cause Analysis

Investigate the Root Cause of product recalls

Why Work with Harford Control

What sets Harford apart is the level of actionable detail in our material consumption reports. Our reports provide granular insights into the root cause of poorly performing materials and downtime. With real-time actionable insights, managers and operators can promptly address issues and take immediate corrective action.

With over half a century of continuous development in performance improvement systems, we remain at the forefront of real-time factory floor MES technology. By actively listening to our clients’ needs, we continuously enhance and refine our material consumption solutions to meet their evolving requirements.

Who We Have Helped

FAQs

-

What is material consumption in manufacturing?

Material consumption refers to the amount of raw materials used in the manufacturing process to produce finished goods. It includes the quantity of materials consumed for each product, component, or unit produced.

-

Why is material consumption important in manufacturing?

Material consumption is important in manufacturing because it directly affects the cost of production and the availability of resources. Efficient material consumption helps minimize waste, reduce costs, optimize inventory management, and support sustainable practices.

-

How can manufacturers track material consumption?

Manufacturers can track material consumption through various methods such as barcode scanning, RFID tagging, automated inventory systems, and integration with manufacturing execution systems. These tools provide real-time visibility into material usage, inventory levels, and facilitate accurate tracking of material consumption.

-

What are the benefits of tracking material consumption?

Tracking material consumption offers several benefits for manufacturers. It helps identify material waste, optimize inventory levels, improve production planning, ensure timely replenishment of materials, reduce stockouts or excess inventory, and enhance overall supply chain efficiency.

-

How can material consumption be reduced in manufacturing?

Material consumption can be reduced in manufacturing through various strategies such as implementing lean manufacturing principles, optimizing production processes to minimize scrap or rework, improving inventory management practices, implementing recycling or reuse programs, and fostering a culture of waste reduction and continuous improvement.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.