Efficiency

Harford Efficiency Solutions place manufacturing personnel firmly in the driving seat with real-time, instantly actionable information, supporting their drive for operational excellence and thereby sustaining their market lead.

A Range of Production & Manufacturing Efficiency Systems

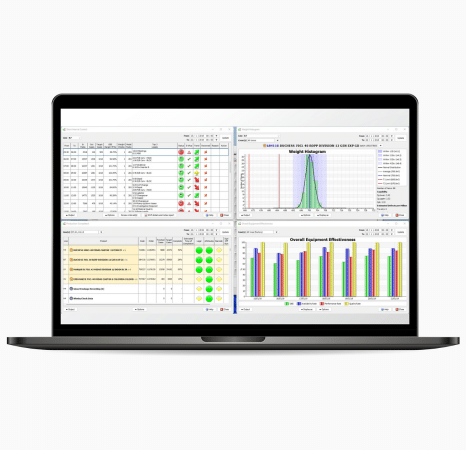

Optimising efficiency is crucial for factories to stay competitive. Harford Control offers comprehensive solutions to enhance manufacturing and production efficiency. Our suite of tools, including OEE/Operational Efficiency, Short Interval Control, Centrelining, Live Reporting, Labour Tracking and Monitoring, and Energy Tracking, empowers manufacturers to streamline operations, identify bottlenecks, reduce downtime, improve resource utilisation, and boost overall productivity, thereby sustaining market dominance.

Real-time Performance, Operational Transparency & Improved Productivity

Harford Manufacturing & Production Efficiency solutions provide a range of benefits to Food & Beverage, Health & Beauty, Pharmaceutical and chemical manufacturers. They enable real-time performance analysis, improve operational transparency, increase productivity, enhance resource allocation, minimise wastage, and reduce transformation costs. By optimising efficiency across all areas of the production process, our solutions help businesses increase output without further capital investment or additional labour, or reduce use of resources (material & time) to achieve the same output.

Performance Analysis

Harford performance analysis thereby becomes the life blood that drives operational excellence. Our comprehensive suite of integrated tools, including OEE/Operational Efficiency, Short Interval Control, Centrelining and Live Reporting, enables manufacturers to monitor performance metrics, identify bottlenecks, make data-driven decisions and drive continuous performance improvement.

Factory Efficiency

Harford factory efficiency helps manufacturers enhance production effectiveness and achieve operational excellence. With solutions such as energy tracking, material consumption analysis, labour tracking and monitoring, and factory stats (mobile apps), manufacturers can streamline operations, improve resource utilisation, achieve greater throughput and reduce transformation costs. We have also added Energy Tracking and Laboratory Information for a more complete picture.

Who We Have Helped

FAQs

-

What are manufacturing efficiency systems?

Production manufacturing efficiency systems are advanced technological solutions aimed at optimizing various aspects of production processes. These systems encompass a range of tools and strategies that leverage data analytics, automation, and real-time monitoring to enhance productivity, minimize waste, and improve overall operational efficiency within a manufacturing environment.

-

How does manufacturing performance impact production efficiency?

Manufacturing performance plays a pivotal role in driving operational efficiency. It encompasses various indicators such as production targets, adherence to schedules, and quality metrics. Analysing performance data allows businesses to pinpoint areas of improvement, implement corrective measures, and ensure that production processes align with organizational objectives.

-

How can production efficiency systems benefit my business?

Production manufacturing efficiency systems offer a plethora of benefits for businesses. By leveraging data-driven insights, automation, and streamlined processes, these systems empower companies to achieve higher production output, reduce operational costs, and enhance the overall quality of their products. This directly translates to improved profitability, greater competitiveness, and the ability to meet market demands effectively.

-

How do manufacturing efficiency systems contribute to waste reduction?

Manufacturing efficiency systems play a crucial role in waste reduction by identifying inefficiencies and areas of excess within production processes. By optimizing workflows, streamlining processes, and ensuring resource utilization, these systems lead to reduced material waste, minimized energy consumption, and overall enhanced sustainability.

-

Can manufacturing efficiency systems enhance product quality?

Yes, manufacturing efficiency systems can significantly impact product quality. By optimizing production processes, reducing defects, and maintaining consistent workflows, these systems directly contribute to improved product quality. The combination of streamlined processes and data-driven insights ensures that products meet or exceed quality standards, enhancing customer satisfaction and loyalty.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.