Profit from Continuous Improvement

We’ve built an information management system that gives everyone in each organisation access to real-time information and traceability, giving such instant insights into production performance, ensuring that every element of each process is optimised, whilst risk and costs are minimised.

Experienced

More than 50 years of experience in manufacturing, research-driven development, and customer input have shaped our current state-of-the-art solution

Globally Trusted

With strong ties to our UK headquarters, Harford solutions are used and supported across the globe – as far away as Australia, India, USA, Africa and Mexico

Valued

Where deployed, the Harford solution becomes an integral part that plays a key role in the success of manufacturing and processing operations

We focus on Continuous Improvement, helping you stay ahead of the Competition

Since being established in 1976, we have developed an enviable track record of innovation and support, so much so that many of our earliest customers are still with us. We pioneered accurate component counting by weight and our electronic weighing systems have been exported to Japan, Brazil and Europe for more than thirty years.

We developed our first computing system in 1979 and were the first to apply statistical process control (SPC) techniques to quantity control systems, to comply with EU Average Quantity Law. We have now evolved into an in-house designer, developer and manufacturer of a uniquely comprehensive real-time information management system – the most developed and cost effective of its kind, available globally.

Why Work with Harford?

Having reviewed many Profit and Loss Accounts recently, we have found that an increasing number of companies have managed to turn in, during very difficult trading circumstances, admirable increases in annual turnover. However, due to rising costs, the benefit of the increased turnover has been either minimised or completely eliminated in the pre-tax net profits.

This indicates that either the raw material costs are too high, the transformation costs from raw materials to finished goods is carrying too much ‘loss’, overheads have risen in line with turnover, but not in line with profit and/or selling prices are fixed by long term contracts or refusal from powerful supermarket customers to accept price increases.

In such circumstances, it is unlikely that manufacturers will gain much traction in reducing the cost of raw materials, nor in the reduction of salary costs, so therefore, it becomes obvious that manufacturers need to work harder and smarter to gain more finished packs for their raw materials, more packs per man hour produced and also fewer costly failures/batch rejections, etc.

This is the area in which Harford specialises, to help you achieve these objectives.

One Solution Multiple Industries

Beverages

Whisky, wine, vodka, beer, spirits, cider, juice, tea, coffee, milk, sport and energy drinks, buttermilk, chocolate and many more.

Food

Dairy, ready meal, seafood, pie, pizza, vegetables, sugar, cereals, confectionery, protein, nuts, meat, biscuits, cookies, crisps and many more.

Pharma

Tablets, capsules, ampoules, cachets, drops and many more.

Cosmetic

Foundation, mascara, moisturisers, cleansers, shampoos, conditioners, hair colours, bubble bath, soap and many more.

Chemical

Salt, chlorine, caustic soda, soda ash, acids, titanium dioxide and many more.

Household Consumer Goods

Wet wipe, laundry detergent, toothpaste, vitamins, cleaning supplies and many more.

We fully Recognise and Understand the Challenging Environment in which our Clients Operate

Our clients are constantly under pressure to improve their performance and, as their partners, we consistently stretch ourselves to help meet their needs.

Most of our clients supply supermarkets in a competitive supply chain, where retailers make increasingly strenuous demands for higher quality, greater consistency, and competitive prices. While this has been good for consumers and supermarkets, it often becomes a logistical and management nightmare for suppliers.

As your partner, we can help you stay ahead, enabling you to minimise risk and cut costs whilst increasing efficiency and profitability. Find out more about our solutions: MES | SPC | OEE | Lab | Paperless Factory | Real-time Information.

Client Case Studies

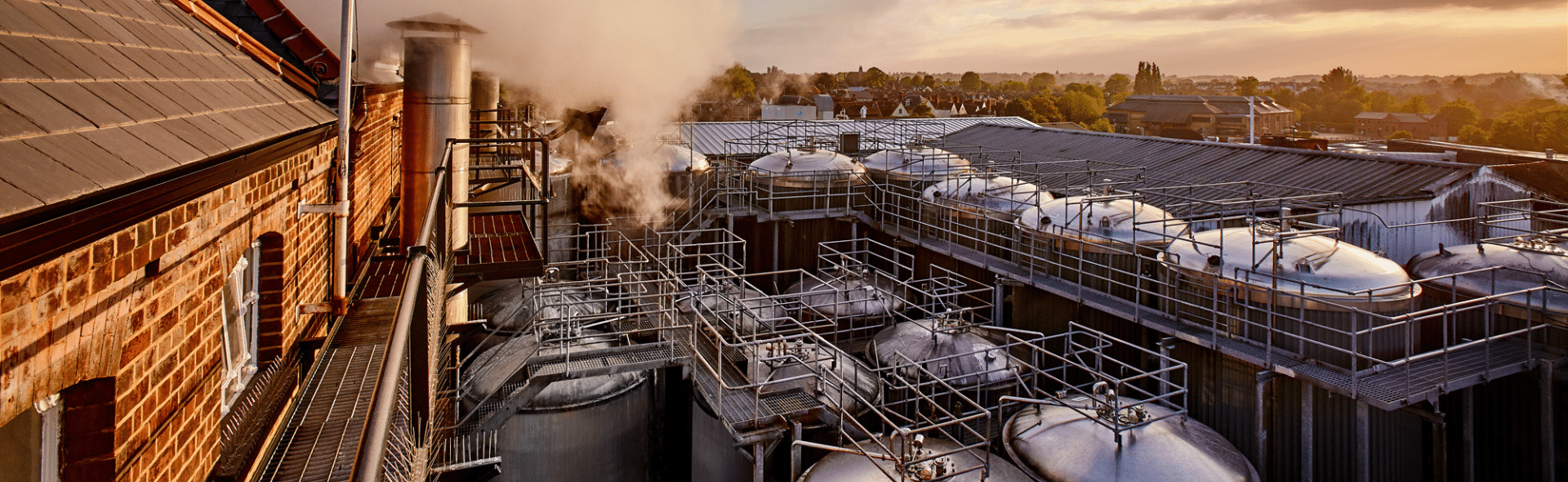

High-end Whisky Bottling

‘One year after implementation and Harford has supported us in reducing our bottling losses to less than 0.1%, and has taken our overall end to end liquid losses down by…

Read more

Full Compliance, No More Print Room

‘Through it’s well structured hardware and software routines, it has helped us to minimise production risk, improve quality consistency and improve efficiency, whilst eliminating most factory floor paperwork and providing…

Read more

Better Brewery Performance

‘We are saving £10,000 p.a. simply with better fill height control, based on the information and guidance provided by the Harford SPC module.’

Read more

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.

FAQs

-

What MES solutions do you offer?

We offer comprehensive Manufacturing Execution System (MES) solutions that optimize production processes, enhance resource utilization, and enable real-time monitoring and control across your manufacturing operations.

-

How can we improve manufacturing performance?

Our MES solutions provide real-time insights, performance analysis, and automated monitoring, leading to streamlined processes, reduced downtime, improved resource allocation, and enhanced overall manufacturing efficiency.

-

What manufacturing compliance solutions do you provide?

We offer integrated solutions that ensure adherence to industry standards, regulations, and quality control measures. Our systems facilitate real-time data tracking, accurate reporting, and automated compliance checks.

-

How can we reduce product defects?

Our MES solutions integrate quality control measures, real-time monitoring, and automated checks to identify defects early in the production process. This leads to reduced defects, improved product consistency, and enhanced customer satisfaction.

-

Can your MES solutions improve manufacturing performance & efficiency?

Yes, our MES solutions optimise production workflows, offer real-time insights, and enable informed decision-making. This leads to enhanced efficiency, minimised downtime, and improved overall manufacturing performance.

-

Do your MES / MIS solutions help improve profitability?

Yes, our MES/MIS solutions lead to reduced operational costs, improved resource utilization, minimized waste, and optimized production. These factors contribute to increased profitability for your manufacturing operations.