Paperless Quality

No more paperwork! Scheduled quality assurance checks with instant verification and corrective action advice to improve quality consistency, invoke Right First Time practices and provide a fully traceable audit trail.

Paperless Manufacturing Solutions

A paperless factory system should be as easy to use as possible, and it should encourage users to only perform and record correct actions and results – it should be hard to make mistakes!

Our system ensures a high level of control by making sure checks critical to your operation are completed at prescribed intervals; failure to do so can result in the line being stopped until supervisor intervention.

- Gain instant visibility, allowing you to quickly identify and address production problems.

- Reliably track every stage of your unique process with 100% traceability.

- No more lost documentation.

- No more transcription errors.

- Maintain consistent product quality.

Do It Right First Time

The development of our quality module started more than 45 years ago, following in the footsteps of Edwards Deming and Walter Shewart, who started the shift away from heavily manual quality inspection towards Right First Time Quality Assurance and developed tools such as Shewart Charts and Statistical Process Control.

Today, Harford Paperless Factory is probably the most comprehensive paperless factory solution, combining decades of experience with continuous improvement, heavily influenced by user input.

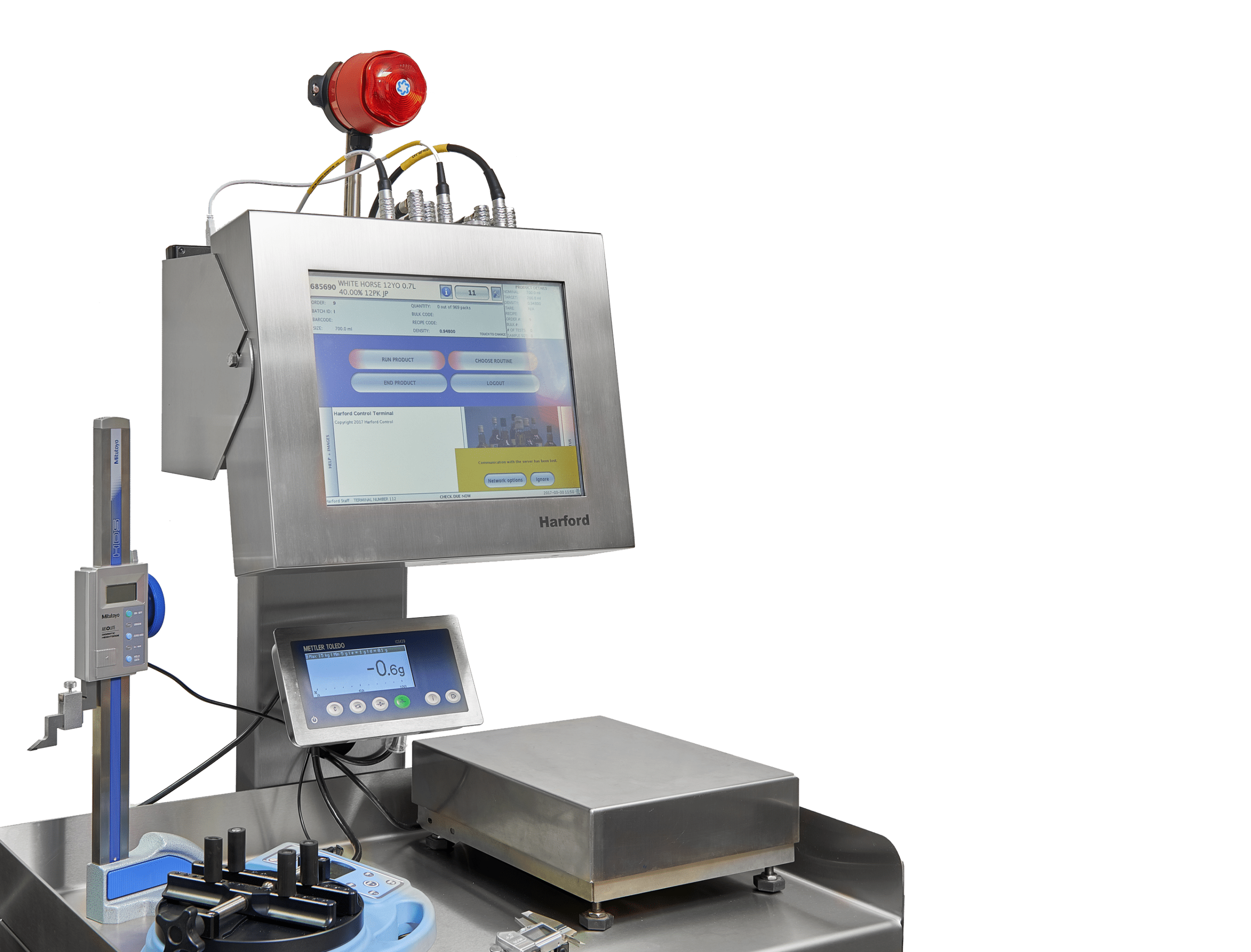

Digital Integration of Peripherals

Our touchscreen terminals are capable of directly capturing results from connected devices, such as scales, torque meters, temperature probes, refractometers, titrators, moisture analysers, calipers, height gauges, O2/CO2 meters, etc. to ensure that information is always correct and reliable.

Together with in-line data capture from scanners, date coders, cameras, sensors, etc., the system provides the opportunity to remove all factory floor paperwork and reduce the need for reviewing and validating compliance to specification.

Instant Verification

A paperless factory system must be as easy to use as possible, and it should encourage users to perform and record all actions and results – this makes it virtually impossible to make mistakes!

Recognising the importance of error proofing, the Harford system ensures a high level of control by making sure checks, critical to each operation, are completed at prescribed intervals. Failure to do so will be instantly displayed on factory management screens and supervisory computer terminals.

Real-time Actionable Information

Get real-time visibility of quality performance through in-depth shop floor data capture, instantly displayed.

Instant Verification

Ensures control with critical checks and timely interventions.

No More Paperwork

Remove all factory floor paperwork, and the need to review paper-based control documents. Paper storage silos eliminated.

Easy and Direct Integration of Peripherals

Easily captured results for seamless data integration and analysis through direct connectivity with peripherals.

Why Work with Harford Control?

Harford Paperless Quality Solutions help manufacturers to ensure product safety and quality compliance with real-time visibility on the shop floor. Our Paperless Quality Management System combines quality control, quality assurance & error-proofing to improve quality consistency.

Who We Have Helped

FAQs

-

What are the benefits of implementing paperless quality systems?

Implementing paperless quality systems offers several advantages. It reduces paperwork, manual errors, and administrative burden, saving time and resources. Digital systems enable real-time data capture, analysis, and reporting, facilitating faster decision-making and proactive quality control. Paperless solutions enhance data integrity, traceability, and document control, promoting compliance with regulatory standards and quality management best practices.

-

How can paperless quality systems improve traceability and compliance?

Paperless quality systems provide robust traceability and compliance capabilities. Digital records capture detailed information about quality processes, inspections, and non-conformances, enabling thorough traceability throughout the production lifecycle. Automated workflows enforce standard operating procedures, ensuring compliance with regulatory requirements. By centralizing and organizing data electronically, organizations can efficiently respond to audits, track product history, and demonstrate compliance.

-

How does real-time data capture contribute to paperless quality?

Real-time data capture is a key aspect of paperless quality systems. It enables instant data collection from production processes, inspections, and quality checks, eliminating delays associated with manual data entry. Real-time data provides immediate visibility into quality performance, allowing for proactive quality control measures and rapid production issue resolution. It enhances data accuracy, timeliness, and responsiveness, promoting effective quality management.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.