Live Reporting, Analysis & Traceability

It has always seemed a ‘missed opportunity’ to the Harford team to simply display current status results.

Wherever possible, the Harford Traffic Lights programme shows action orientated information (not just data) to drive the right actions at the right time, which has been proven to have a huge impact on performance improvement, quality consistency and customer satisfaction.

Live Reporting Solutions – Gain Insights & Track Manufacturing KPIs

As statistical results are analysed and prioritised, it makes sense to display these results in real time to prompt action.

The availability of up-to-date information is what drives client decision-making. Visibility is key to motivating the whole team to take action when prompted and thereby drive performance improvement.

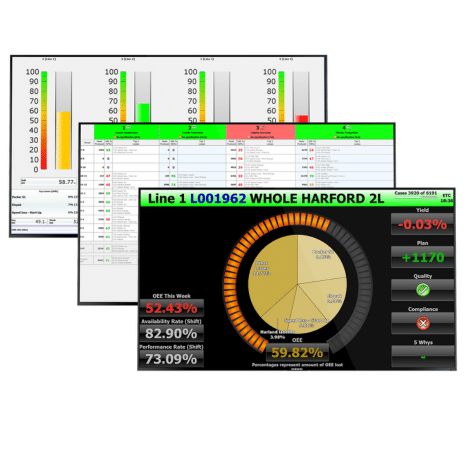

Harford’s Traffic Lights reporting tool makes visible all relevant KPIs in real-time. Manufacturers can gain actionable insights, track key performance indicators, identify trends, and make data-driven decisions, in real time, with less work, fewer process adjustments and consequential efficiency improvements.

Real Time Visibility and Production Performance

Live Reporting solutions enable decision making by providing real-time visibility to support production performance. With always up-to-date information and instant notifications, users make informed decisions and resolve issues promptly. These solutions ensure flexibility and agility in a rapidly evolving market.

Instant Visibility – the Key to Success

Our manufacturing reporting solutions offer automated data capture and analysis, minimising manual data entry and enabling quick and accurate actions to be taken. Harford Traffic Lights software prioritises key issues for maximum gains, whilst comprehensive reports provide in-depth access to details and root cause analysis. The availability of up-to-date information across multiple platforms motivates the entire team to take timely actions.

Live Reporting & Analysis

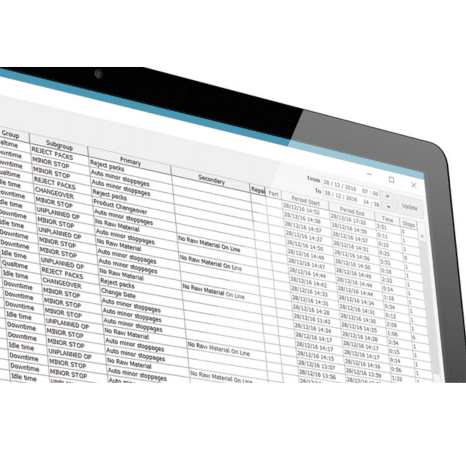

All data captured on the factory floor, from manual entry to direct capture via OPC and PLC links, is transferred to the central Harford system server, where it is automatically processed, interpreted, organised, and structured to turn it into meaningful, useful, and actionable information.

There is no more need to spend hours typing manually captured data from paper sheets into Excel, just to be able to perform basic calculations!

Prioritisation

The danger in having lots of data is ‘analysis paralysis’, where too much information inhibits the decision-making process and actions may not be taken at all. As the system already holds so much data, it makes better use of your time to let the computer do the analysis and prioritisation automatically.

Our unique Traffic Lights programme highlights the main issues that need to be dealt with to achieve the greatest gains. At the same time, a wide range of reports gives in-depth access to all details, where required.

Distribution

All information is available to the whole business, on multiple platforms, to ensure that there is only ‘one version of the truth’. We provide a combination of PC-based reporting, large information screens, computer tablets and mobile reporting apps.

Live Reporting Systems for A Range of Industries

Harford live reporting solutions play a vital role in industries such as FMCG, Food & Beverage, Heath & Beauty, Pharmaceutical and Chemical, where timely decision-making and operational agility are crucial. By implementing Live Reporting solutions, manufacturers can quickly identify production issues, address them promptly, optimise resources, and meet customer demands effectively.

Real-time, Live Reporting of Manufacturing Data

Real-time manufacturing analytics provide a powerful advantage for manufacturers seeking to optimise production processes. With real-time visibility, data analysis, auditing, and traceability, factories can monitor live data streams, detect anomalies, and take immediate action. Real-time Manufacturing Analytics enable proactive decision-making, improved process control, enhanced efficiency, and improved ‘door-to-door’ OEE.

Real-Time Visibility

Instant access to up-to-date information on production performance

Data Analysis

Auto-analyse captured data for valuable insights and informed decision-making

Auditing and Traceability

Ensure accountability and traceability throughout the manufacturing process

Global Group Reporting

Consolidated reporting across multiple locations for comprehensive analyses

Tablets & Mobile

Access and manage data on-the-go for increased flexibility and efficiency

Why Work with Harford Control?

To those who have worked with us, it’s obvious!

Leading edge, comprehensive and integrated real time information, presented through the most friendly and accessible methods, in plain language, to encourage instant performance improvement actions by the whole team. The granularity and drill-down capabilities of our reports make it easy to track the root cause of any issues and turn insights into actionable improvements.

Worldwide 24/7 support from friendly, trained engineers.

Who We Have Helped

FAQs

-

What is Live Reporting?

Live Reporting is a real-time reporting process that provides up-to-date and accurate information on various aspects of manufacturing operations. It involves capturing data directly from production systems and presenting it in a visually appealing and user-friendly format, allowing stakeholders to monitor key metrics, track performance, and make informed decisions in real time.

-

What are the benefits of Live Reporting?

Live Reporting offers several benefits, including improved visibility into production performance, enhanced decision-making, proactive issue identification, and faster response times. It enables real-time monitoring of key metrics, identifies trends and patterns, supports continuous improvement initiatives, and fosters a culture of data-driven decision-making throughout the organization.

-

How does Live Reporting work?

Live Reporting works by collecting data from sensors, machines, and other sources in real time. This data is then processed and presented through intuitive dashboards, charts, and graphs, providing a comprehensive view of production performance. Users can access the reports on their devices and make data-driven decisions instantly, promoting agility and proactive management.

-

How can Live Reporting improve operational efficiency?

Live Reporting improves operational efficiency by providing real-time insights into production processes. It helps identify bottlenecks, inefficiencies, and areas for improvement, enabling timely intervention and optimization. With access to up-to-date information, teams can proactively address issues, allocate resources effectively, and make informed decisions to streamline operations and maximize productivity.

-

How can Live Reporting support continuous improvement efforts?

Live Reporting supports continuous improvement efforts by providing real-time visibility into performance metrics and trends. It helps identify areas of waste, quality issues, and process inefficiencies, allowing teams to take immediate corrective actions. The availability of accurate and timely data facilitates data-driven problem-solving, fosters collaboration, and promotes a culture of continuous improvement.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.