Autocoding

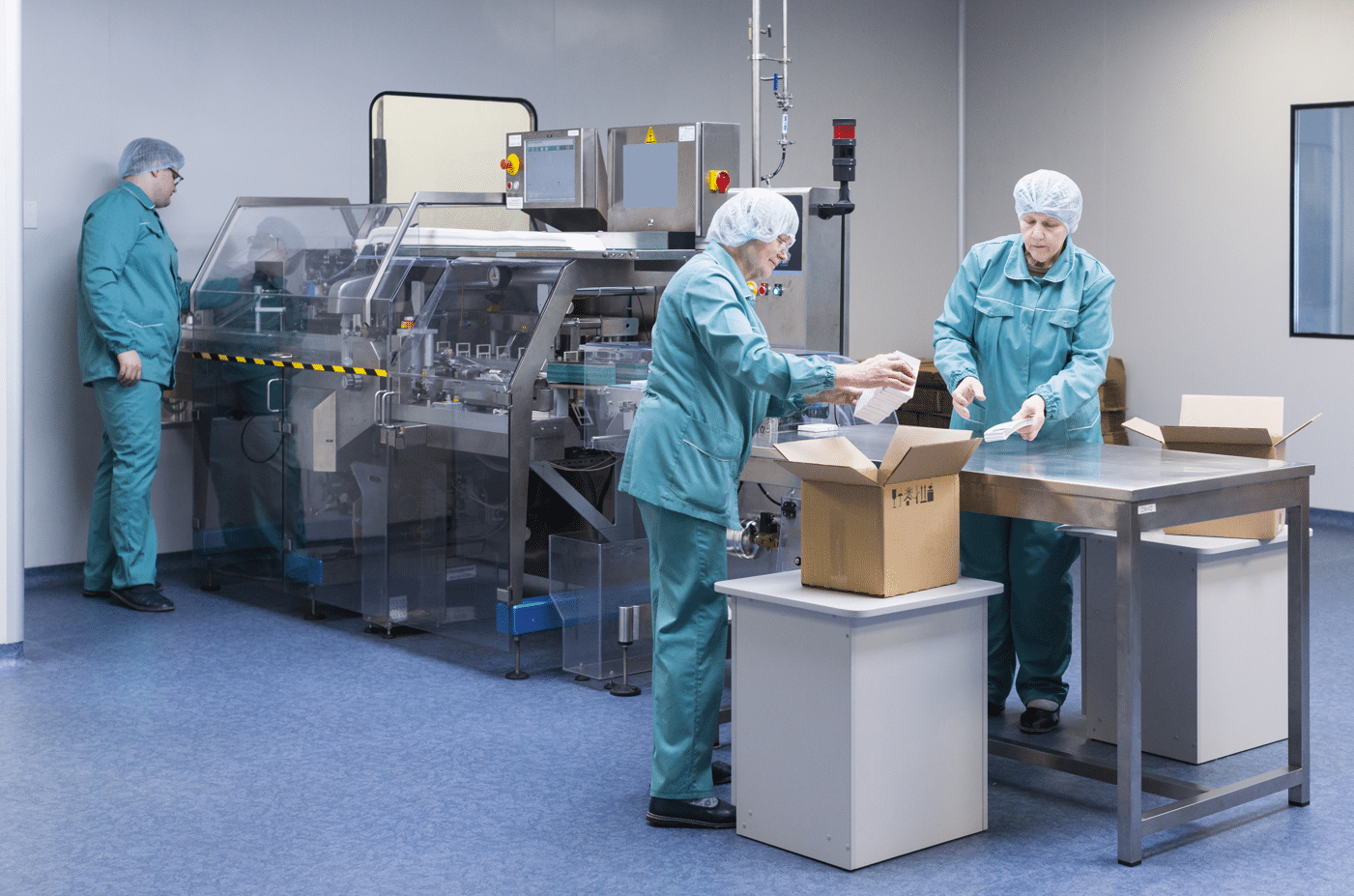

Harford AutoCoding Solutions use automation, accurate date coding setup, label verification and in-line barcode scanner configuration to prevent non-conformances, reduce changeover times, minimise the risk of human errors and decrease the cost of manufacturing.

Autocoding - Reducing Manufacturing Costs & Error Reduction

Call it Autocoding, Coding & Labelling Compliance, or Mix-up Prevention – in the end it is simply Good Manufacturing Practice (GMP). We use automation to prevent non-conformances and reduce the cost of manufacturing at the same time.

Harford Autocoding contains production line automation, accurate date coding set up, label verification and in-line barcode scanners configured to ensure a higher validation of packs. This way, we can help manufacturers to eliminate risks, prevent non-conformances, minimise human errors and avoid unnecessary wastage.

Efficient, Accurate Coding & Supporting Regulatory Compliance

Harford Autocoding solutions help manufacturers eliminate EPWs, batch rejections and fines, minimise human error, reduce changeover times, and provide instant non-conformance alerts. These benefits ensure efficient and accurate coding, regulatory compliance, and cost savings, making them essential for FMCG, Food and Beverage, Pharmaceutical, Cosmetics, and Chemical manufacturers.

Real-time Actionable Information – Reducing Risk and Human Error

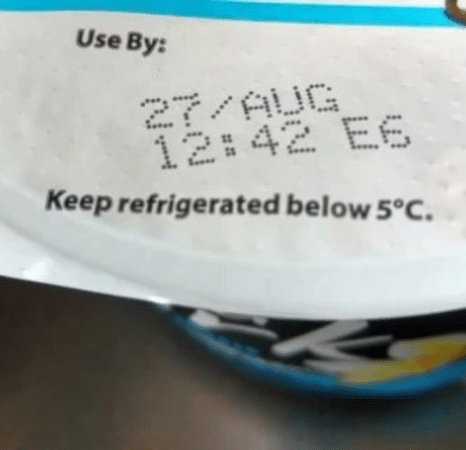

On hundreds of production lines, we help to ensure that printed date codes on products are always accurate, every single day and night.

Rather than relying on operators to manually configure any printer on a production line, Harford Autocoding sends real-time actionable information directly to each device. This eliminates the risk of human error and reduces changeover times, resulting in higher production efficiency and yields.

Through the integration of other business systems, e.g. ERP, MRP, or product specification solutions, Harford always sends the correct information to any packaging line device.

Autocoding Systems for the FMCG, Food & Drink, and Pharma Industries

In highly regulated industries like FMCG, Food and Drink, and Pharmaceuticals, accurate product labelling is critical. Harford Autocoding ensures compliance with industry-specific regulations, reduces the risk of mislabelling or misidentification, and protects consumer safety. By implementing the Harford Autocoding solution, manufacturers can uphold their reputation, avoid costly recalls, and maintain trust with retailers, consumers and regulatory bodies.

Accurate Date Coding

Harford autocoding sends real-time actionable information directly to those who need it

Allergen Control

Ensure allergen information on each package and outer case is accurately labelled

Batch Control

Efficiently automate coding processes with streamlined batch control capabilities

Auto Laboratory Triggers

Automatically initiate certain actions based on predefined triggers

Integrated MES Approach

Foundation for comprehensive factory data capture and MES

Our Autocoding Solutions – Working with Harford Control

Despite several supermarket chains introducing codes of practice for label verification, batch rejections increased between 2014 & 2015 by more than 74%. Most of these were not due to label verification issues, which serves to illustrate that, important as label verification is, there are many other controls to be effectively managed in order to minimise the risk of batch rejections.

This is where our holistic systems approach really scores over other autocoding systems, as it not only helps supermarket suppliers to minimise their coding & labelling errors, but when included as part of the Harford integrated solution, at the same time, can improve production line efficiency and performance.

Who We Have Helped

FAQs

-

What is autocoding in manufacturing?

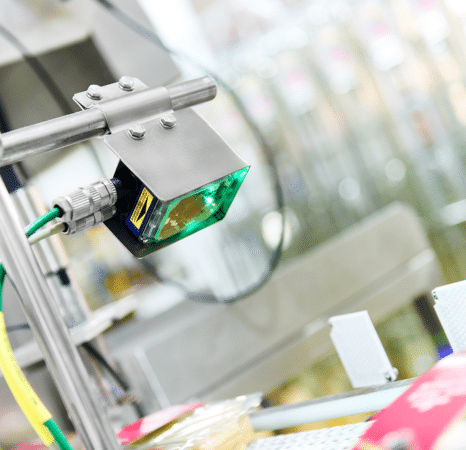

Autocoding is a process in which automated systems and software are used to assign product codes or labels to manufactured goods. It eliminates the need for manual coding by automatically generating and applying accurate and consistent codes based on predefined rules. Autocoding systems utilize technologies such as barcode scanners, optical character recognition (OCR), and data validation algorithms.

-

How does autocoding work?

Autocoding works by capturing relevant product information, such as batch codes, expiration dates, and product identifiers, and using predefined rules and algorithms to automatically assign the appropriate codes or labels. It typically involves scanning or reading product data from barcodes or other data sources, validating the information, and generating and applying the required codes onto the products.

-

What role does autocoding play in regulatory compliance?

Autocoding plays a crucial role in regulatory compliance by ensuring that products are accurately and compliantly coded according to industry regulations and standards. It helps manufacturers meet labelling requirements, including batch coding, expiration dating, allergen labelling, and country-specific regulations. Autocoding software can incorporate validation checks to ensure coding accuracy and compliance with applicable regulations.

-

Can autocoding integrate with existing production lines?

Yes, autocoding systems can integrate with existing production lines and equipment. They can be seamlessly integrated with packaging machines, labelling systems, conveyor belts, and other production line components. Autocoding software can communicate with production line control systems, allowing for real-time data exchange, synchronization of coding operations, and automatic adjustment of coding parameters.

-

How does autocoding improve production efficiency?

Autocoding improves production efficiency by automating the coding process, eliminating the need for manual data entry or coding adjustments. It reduces the time required for coding tasks and minimizes the risk of errors, allowing for faster and smoother production flows. Autocoding systems can integrate with production lines, enabling seamless coding operations and optimized overall equipment effectiveness (OEE).

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.