Materials & Process

Quality Control

Harford Materials and Process Quality Solutions help manufacturers ensure consistent quality from raw materials to finished goods. It’s about getting it right the first time and every time. These solutions encompass Materials Quality and Process Quality.

Material & Process Quality – Instant Verification & Actionable Insights

Harford materials & process quality control solutions ensure consistent quality from raw materials to finished goods for FMCG, food and beverage, pharmaceutical, cosmetics, and chemical manufacturers. With end-to-end traceability, 5 Whys and Fishbone Diagrams, you can easily identify the root cause of quality issues, ensuring exceptional product standards throughout production.

Our aim is to help you achieve this. We aim to empower your operators through scheduled quality assurance checks that offer instant verification and corrective action advice. We also provide the management team with exception notifications, a fully traceable audit trail, and real-time reports.

Consistent Product Quality & Regulatory Compliance

Harford material and process quality control is crucial for FMCG, food and beverage, pharmaceutical, cosmetics, and chemical companies. It ensures consistent product quality, regulatory compliance, cost reduction and customer satisfaction.

- Minimise Risk: Control allergens, minimise human error, instantly detect exceptions, to ensure sustainable quality and legal compliance

- Fewer Recalls: Ensure accurate date coding and correct labelling, with full traceability from raw materials to finished goods

- Lower Cost: Reduce wastage of raw materials and labour, whilst optimising processes to minimise production costs

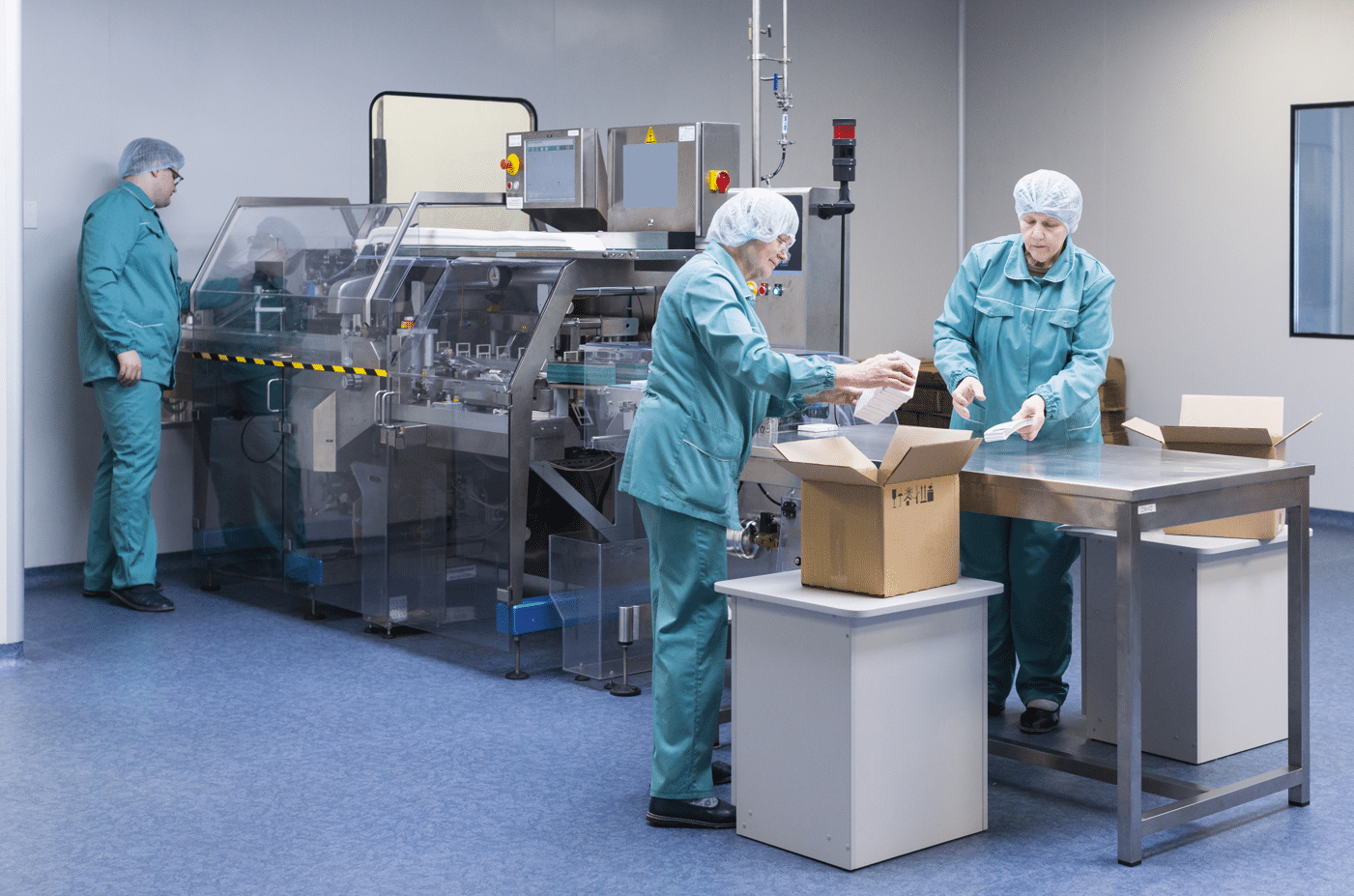

Manufacturing & Production Process Quality

Optimise process control and drive efficiency in manufacturing and production with our innovative MES software for exceptional product quality in the FMCG, food and drink, and pharmaceutical industries.

Lab Quality

Ensuring excellence in laboratory operations and processes

Paperless Check/Quality Check

Streamlining inspections and quality checks with digital solutions

Quality Assurance (QA) & Quality Control (QC)

Maintaining consistent and high-quality standards throughout production

100% Traceability

Tracking and documenting every step for complete product transparency

Integrated Peripherals

Seamlessly connected, thereby optimising peripheral equipment for efficiency

Start-Up Checks

Conducting thorough assessments to ensure smooth production initiation

Why Choose Harford Control's Materials & Process Quality Solutions?

We provide the granularity necessary to drill down to the root cause of quality issues. No other solutions offer such in-depth reports to provide actionable insights. Our solutions enable managers and operators to make informed decisions and take immediate action, based upon real-time information.

With our cutting-edge materials & process quality solutions, you can minimise production risks and wastage, ensure highest levels of quality consistency, minimise wastage and improve manufacturing performance.

Who We Have Helped

FAQs

-

What is materials and process quality in manufacturing?

Materials and process quality in manufacturing refers to the measurement and control of raw materials used, and the production processes involved. It focuses on ensuring that the materials meet agreed quality standards and that the manufacturing processes are performed consistently and efficiently to produce high-quality products.

-

Why is materials and process quality important in manufacturing?

Materials and process quality is crucial in manufacturing as it directly impacts the overall product quality, reliability, and customer satisfaction. By maintaining strict control over the materials used and manufacturing processes, manufacturers can minimise defects, reduce waste, improve efficiency, and deliver products that meet or exceed customer expectations.

-

What are the key elements of materials and process quality?

The key elements of materials and process quality include rigorous inspection and testing of raw materials, adherence to quality standards and specifications, process optimisation and standardisation, continuous monitoring and measurement, root cause analysis, together with implementation of corrective and preventive actions. These elements ensure that materials and processes consistently meet quality requirements.

-

How can materials and process quality control reduce wastage in manufacturing?

Materials and process quality helps reduce wastage in manufacturing by identifying and addressing potential and actual issues early in the production process. By controlling the quality of raw materials and optimising manufacturing processes, manufacturers can minimise scrap, rework, and product failures, leading to improved material utilisation, reduced wastage, and reduced production costs.

-

Can materials and process quality be measured and monitored?

Yes, materials and process quality can be measured and monitored through various techniques and tools. These include statistical process control (SPC), process capability analysis, quality audits, inspections, testing, and data-driven metrics. By monitoring key quality indicators and analysing data, manufacturers can identify trends, detect deviations, and proactively maintain/improve materials and process quality.