Lab Quality

Harford’s Laboratory Information Management Systems (LIMS) seamlessly integrate inspection, track and trace capabilities, automated sampling, Lab MC control and taste panel management. These systems assist manufacturers in efficiently capturing, analysing, and reporting data, ensuring precision and compliance.

Lab Quality Solutions – Optimising Manufacturing and Production Quality

Harford Laboratory Information Management Systems (LIMS) are designed to streamline and automate laboratory workflows, data management, and sample tracking. LIMS facilitates efficient data capture, analysis and reporting, ensuring accuracy and compliance.

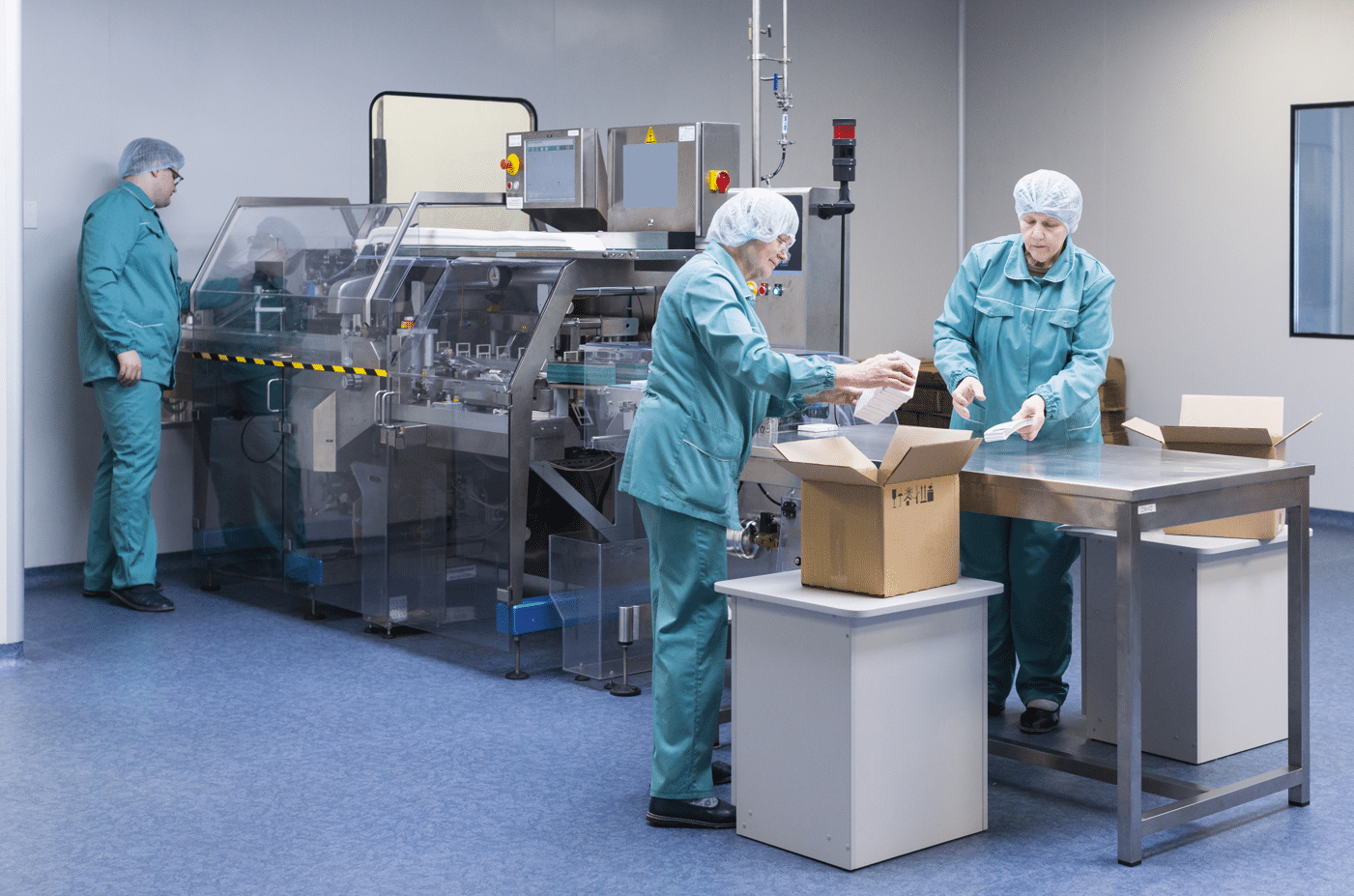

Harford Lab Quality Solutions empower manufacturers within the FMCG, food and beverage, pharmaceutical, cosmetics and chemical sectors to optimise their production and manufacturing processes. By automating tasks such as material usage confirmation, bulk material tracking, and informing lab teams of sampling requirements, we ensure compliance, reduce risks and enhance efficiency. Real-time monitoring and seamless integration of lab equipment enables proactive management of non-compliant products.

Laboratory Information Management Systems (LIMS)

Whether you are weighing, titrating, using gas chromatography or other equipment, all results can be easily entered into the Harford system.

At that time and/or, files can be reopened at a later date to enter results (for example microbiological growth checks).

Laboratory results could be entered into fixed terminals, PCs and tablets. Where possible and appropriate, certain pieces of laboratory equipment with digital output can be connected directly to Harford devices for direct data transfer, thereby eliminating the need for keyboard entries and further minimising the risks of operator error.

Streamline Laboratory Operations

Harford lab quality solutions enable you to streamline your lab operations, reducing manual processes and increasing productivity. Our software automates routine tasks, optimises workflow, and facilitates seamless data management, freeing up your valuable resources to focus on critical analysis and decision-making. With Harford lab quality solutions, you can reduce changeover time and improve overall manufacturing effectiveness.

Ensure Regulatory Compliance

Staying compliant with stringent regulatory standards is of utmost importance in industries like FMCG, food and beverage, pharmaceutical, cosmetics and chemical. Harford lab quality solutions provide robust compliance features, such as inspection, track and trace, auto sampling, Lab MC control, heldware and taste panel tailored to your specific industry requirements. Our software ensures adherence to Good Manufacturing Practice (GMP), ISO standards, FDA regulations, and other industry-specific guidelines. By implementing Lab Quality solutions, you can eliminate risks, ensure product quality compliance and monitor non-conformances from notification to resolution.

Maximise Quality Control

Maintaining exceptional quality control is non-negotiable when it comes to manufacturing products for consumption or medication. Harford Control equips your factory with integrated solutions to maximise quality control throughout the production process. With real-time monitoring, automated data capture, and comprehensive traceability, you can proactively identify deviations, ensure consistent product quality, minimise defects and product recalls, and protect your brand reputation.

Drive Data-Driven Decision Making

Harford Control’s MES solutions provide comprehensive data management and analytics capabilities, empowering you to make data-driven decisions with confidence. Our software collects and consolidates data from various sources, generating insightful reports, visualisations, and dashboards. Harness the power of Harford Control’s analytics to identify trends, optimise processes, uncover hidden opportunities, and continuously improve your manufacturing and production quality.

Materials Compliance

Ensure correct usage for regulatory compliance.

Bulk Material Evaluation & Tracking

Track and trace approved materials throughout the production process.

Automated Sampling & Labelling

Notify lab team, print sample labels for compliance and risk reduction.

Lab Equipment Integration

Automatically link peripheral equipment to mitigate risks.

Non-Compliant Product Monitoring

Track and take action on non-compliant products.

Why Work with Harford Control?

The continuous development of our performance improvement systems for more than half a century keeps us at the leading edge of real time factory floor MES technology. No other single company has created such an impressively integrated set of production modules which so seamlessly work together to form the most comprehensive picture of factory performance.

With our cutting-edge laboratory quality solutions, you can minimise production risks and wastage, together with increased production effectiveness, whilst maintaining the highest levels of quality consistency.

Whether collecting information from the laboratory, goods-inwards or throughout production, Harford has the optimum solution.

Contact us today to learn more and take the first step towards achieving laboratory excellence and manufacturing success.

Who We Have Helped

FAQs

-

What is Lab Quality (LIMS)?

Lab Quality refers to the management and control of laboratory processes and data using a Laboratory Information Management System (LIMS). LIMS is a software solution that automates and streamlines laboratory workflows, sample tracking analyses, data management, and quality control, ensuring accurate and efficient lab operations with full ease of traceability.

-

How does Lab Quality (LIMS) benefit laboratories?

Lab Quality (LIMS) offers several benefits to laboratories. It improves data integrity, reduces manual errors, and enhances traceability of samples and test results. LIMS enables efficient sample management, scheduling, and tracking, optimizing resource utilization and turnaround times. It also facilitates compliance with regulatory requirements and standards, ensuring quality and accuracy in lab operations, without paper recording.

-

What are the key features of Lab Quality (LIMS)?

Key features of Lab Quality (LIMS) include sample tracking and management, test scheduling, instrument integration, data capture and analysis, quality control management, and reporting capabilities. LIMS provides a centralized database for efficient data storage, retrieval, and sharing, ensuring consistency, accuracy, and compliance in laboratory processes. Most of all, LIMS is a service to production to ensure that only safe products are produced in a safe manufacturing environment.

-

How does Lab Quality (LIMS) improve data management?

Lab Quality (LIMS) improves data management by automating data entry, reducing manual transcription errors, and providing secure and centralized storage of test results and related information. LIMS enables efficient data retrieval, analysis, and reporting, facilitating data-driven decision-making and ensuring data integrity and traceability throughout the laboratory workflow. Effective laboratory tests can also ‘flag up’ out of spec results as early as possible.

-

What are the benefits of integrating Lab Quality (LIMS) with other systems?

Integrating Lab Quality (LIMS) with other systems, such as instrument systems, enterprise resource planning (ERP), offers several benefits. It streamlines data transfer, reduces manual data entry, enhances data accuracy, and improves workflow efficiency. Integration enables seamless data exchange, increases productivity, and ensures data consistency across different systems. Integrated WMS can also ‘block’ production and/or dispatch where results are out of spec. Thereby, saving expensive materials, production time and also protecting consumers and the company’s brand/reputation.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.