Production Quality

Harford Production Quality Solutions help manufacturers tackle the challenges of manual transcription, human errors and non-conformances. Do it Right First Time. Harford Production Quality Solutions include Paperless Quality, Lab Quality (LIMS), and Traceability.

A Range of Production & Manufacturing Quality Control Solutions

Harford Production Quality Solutions resolve the manufacturing quality challenges factories face with manual transcription and analysis of results, repetitive handling of non-conformances. Human errors are minimised through increased operational discipline and more in-depth training.

By implementing our solutions, our clients benefit from a reduction in defects, enhanced product consistency and streamlined workflows. Increased operational efficiency leads to greater profits and increased customer satisfaction. Our focus on production quality empowers businesses to deliver superior products, whilst maximising productivity and minimising operating costs.

Manufacturing Quality Solutions

Harford’s production quality solutions include a range of cutting-edge software tools. These enable the elimination of paperless recording and risks involved in the transposition of paper records to computers.

Our laboratory quality management system (LIMS) allows instant measurement and notification of laboratory issues, together with end-to-end traceability.

These systems provide comprehensive quality management software to manufacturers, enabling precise production control, streamlined processes, and excellent quality control in manufacturing.

Production Quality Software

Harford production quality software enables instant visibility, leading to more effective production control and product management. It streamlines processes, facilitates real-time monitoring, captures critical data, enables instant analysis and reporting, and ensures adherence to stringent quality standards.

Paperless Quality Solutions

Streamline your operations by eliminating paperwork and embracing efficiency. Benefit from scheduled quality assurance checks, instant verification, expert corrective action advice, and a meticulously traceable audit trail. Achieve unparalleled consistency and uphold the “Right First Time” principle with confidence.

Lab Quality

Elevate your operations with the Harford Lab Quality Management System (LIMS). Optimise workflows, enhance data management, ensure regulatory compliance, and achieve superior quality control in your lab environment, whilst minimising your dependence upon paper.

Product Traceability

Gain complete visibility and control over your factory operations with our End-to-End Traceability solutions. Track every step of the production process, enhance quality control, ensure compliance, and improve overall operational efficiency.

Why Work with Harford Control?

Over several decades, Harford Control has worked tirelessly with a wide range of factories across five continents to help optimise their production performance.

With the Harford Manufacturing Execution System (MES) tailored to individual needs, it becomes easier to reduce errors, find the hidden wastage and consequently become more efficient, whilst continuing to deliver consistently high quality products, thereby making each business more profitable and sustainable.

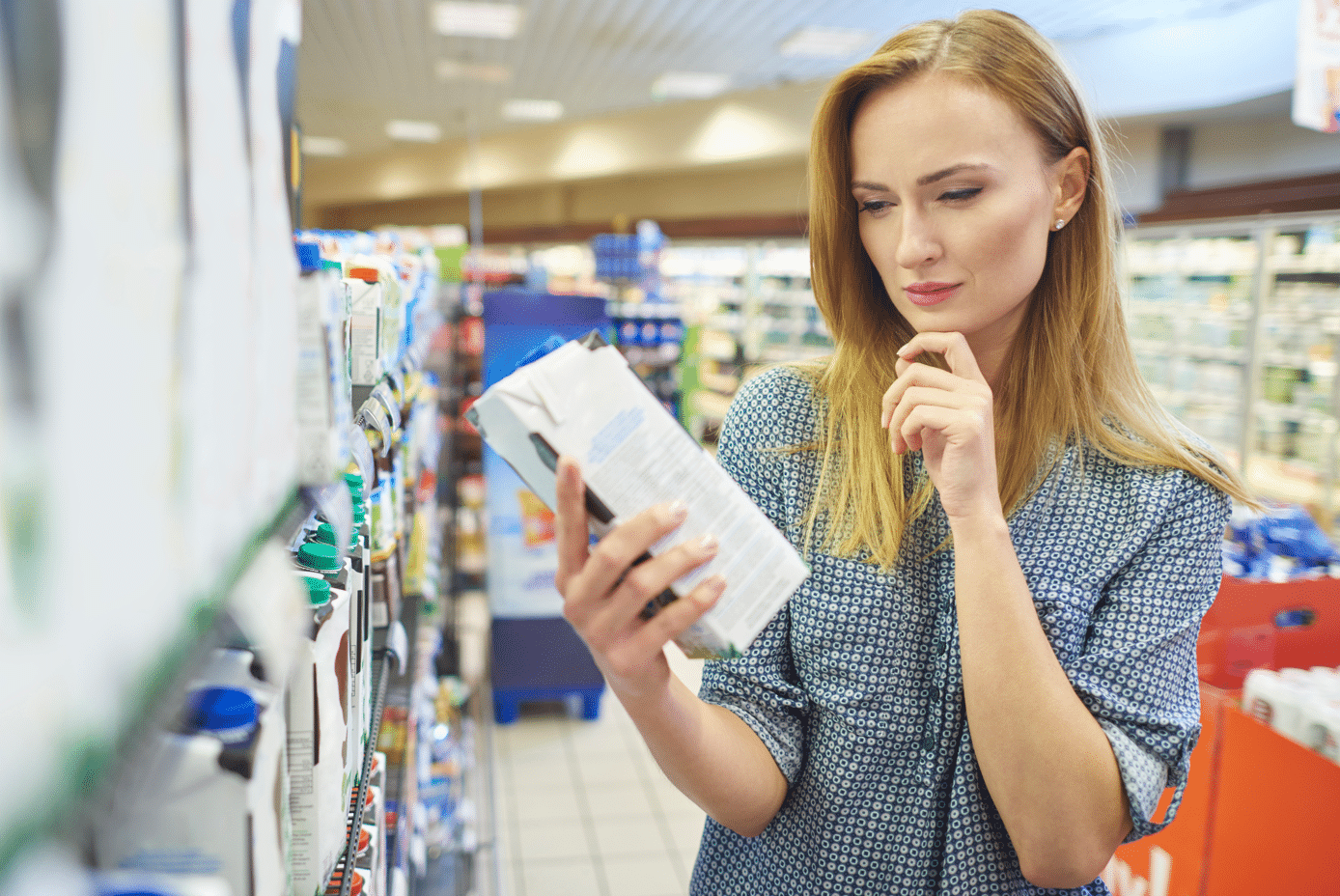

Most manufacturers are facing ever increasing input and transformation costs with few opportunities to increase the output price to their customers (High Street Multiples).

This encourages manufacturers to look more deeply into their production processes to find the hidden costs, eliminate wastage and thereby improve efficiency without compromising quality.

The problem of rising input costs and fixed output costs is nothing new and will not end. Therefore performance improvement to drive down transformation costs must be continuous for the business to sustain its market position and avoid losing its place on supermarket shelves to the competition.

Who We Have Helped

FAQs

-

What is production quality?

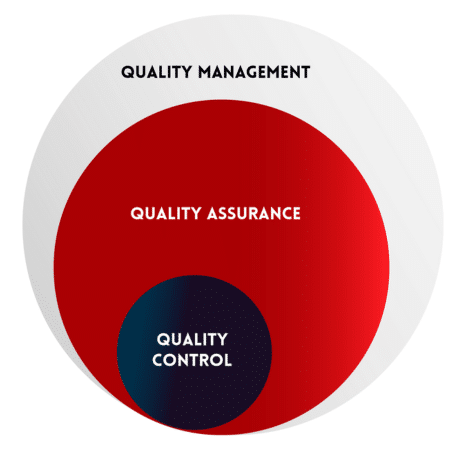

Production quality refers to the level of excellence or conformance achieved in the manufacturing process, ensuring that products meet established standards and customer expectations. It involves implementing rigorous quality control measures, conducting inspections, and employing advanced techniques to deliver consistent, high-quality products.

-

Why is production quality important?

Production quality is vital for customer satisfaction, brand reputation, and market competitiveness. It ensures that products meet or exceed customer expectations, minimizes defects, reduces waste, and enhances overall operational efficiency. By prioritizing quality, manufacturers can build trust, gain a competitive edge, and drive long-term success.

-

What are common quality issues in manufacturing?

Common quality issues in manufacturing include defects, variations in dimensions or colour, inadequate packaging or labelling, contamination, process inefficiencies, and deviations from regulatory requirements. Identifying and addressing these issues promptly through effective quality control measures is crucial to ensure consistent product quality and meet customer expectations.

-

What is the role of quality control in production?

Quality control plays a pivotal role in ensuring that products meet specified quality standards and conform to customer requirements. It involves systematic monitoring, inspection, and testing at various stages of the production process to detect and address deviations or defects promptly. By proactively managing quality, manufacturers can identify improvement opportunities, minimize risks, and deliver products that meet or exceed expectations.

-

What are the key benefits of focusing on production quality?

Focusing on production quality yields several key benefits. It leads to higher customer satisfaction by delivering products that consistently meet or exceed expectations. Quality-focused manufacturing reduces costs associated with rework, warranty claims, and customer complaints. It enhances brand reputation, fosters customer loyalty, and provides a competitive advantage in the market. Additionally, improved quality often results in increased operational efficiency and productivity.