Inline Inspection

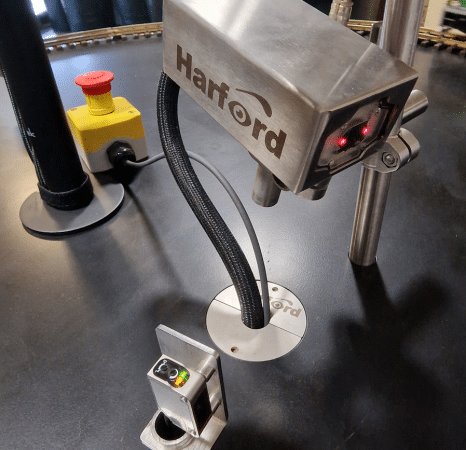

Harford Inline Inspection Solutions help manufacturers ensure error detection, defect prevention and adherence to retailers’ codes of practice. These solutions can include Vision Inspection and Barcode Inspection.

Inline Inspection Solutions – Ensuring Product Quality & Compliance

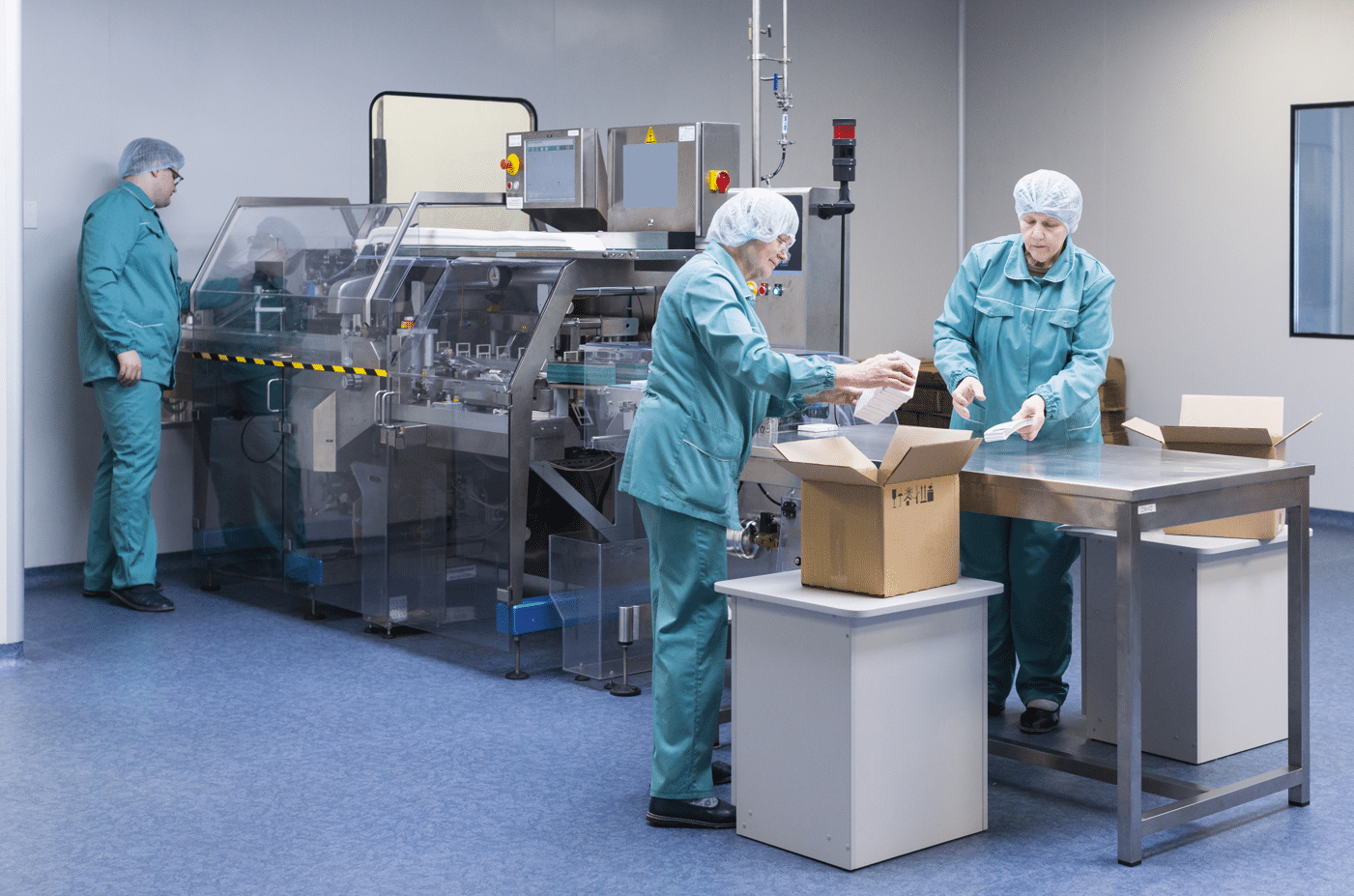

Harford inline inspection solutions help manufacturers ensure product quality and compliance. We help to empower FMCG, Food & Beverage, Health & Beauty, Pharmaceutical, and Chemical Manufacturers to achieve accurate and efficient compliance-focused quality control. From vision inspection to inline barcode scanning, our comprehensive solutions ensure error detection, defect prevention and adherence to retailers’ codes of practice. With event traceability, rejection systems, pattern matching, and component matching, businesses can confidently deliver safe, compliant and high-quality products, every time.

Vision Inspection & Barcode Inspection - Ensuring Compliance and Product Quality

Harford inline inspection solutions include vision inspection and barcode inspection, providing robust quality control measures for manufacturing industries to meet regulatory compliance. When barcode verification is not possible due to artwork limitations, vision inspection may be critical for factories to ensure allergen-free products and correct printing.

Vision Inspection - Precise Quality Control for Manufacturing Compliance

When barcode or 2D code verification is not practicable due to artwork constraints, consider multiple scanners or a vision inspection solution. Automatic on-line vision inspection can be critical for FMCG, food and beverage, health and beauty, pharmaceutical and chemical manufacturers to ensure allergen-free products as well as precise on-line printing of date codes, origin details, and other information. In-line cameras allow for comprehensive image-based inspection to ensure client specification compliance and consumer protection.

Barcode Inspection - Accurate Product Identification for Compliance

Harford barcode inspection solutions empower manufacturers with accurate, reliable, and compliant barcode scanning and verification. Our solutions offer 1D and 2D barcode verification, ensuring precise matching of component parts to products. By detecting barcode errors and ensuring compliance, businesses can optimise processes, eliminate risks, and deliver products with high level of precision and confidence.

Why Work with Harford Control?

Over several decades, Harford Control has worked tirelessly with a wide range of factories across five continents to help optimise their production performance.

With the Harford Manufacturing Execution System (MES) tailored to individual needs, it becomes easier to reduce errors, find the hidden wastage and consequently become more efficient, whilst continuing to deliver consistently high quality products, thereby making each business more profitable and sustainable.

Most manufacturers are facing ever increasing input and transformation costs with few opportunities to increase the output price to their customers (High Street Multiples).

This encourages manufacturers to look more deeply into their production processes to find the hidden costs, eliminate wastage and thereby improve efficiency without compromising quality.

The problem of rising input costs and fixed output costs is nothing new and will not end. Therefore performance improvement to drive down transformation costs must be continuous for the business to sustain its market position and avoid losing its place on supermarket shelves to the competition.

Who We Have Helped

FAQs

-

What is inline inspection in manufacturing?

Inline inspection is a quality control process that involves inspecting products during the manufacturing process at various stages. It uses specialized equipment and sensors to detect defects, measure dimensions, and assess product quality in real-time. Inline inspection helps identify issues early, enabling prompt corrective actions and ensuring consistent production of high-quality products.

-

Why is inline inspection important in manufacturing?

Inline inspection plays a vital role in manufacturing by ensuring product quality and preventing the production of defective items. It helps identify and address issues during the manufacturing process, reducing the likelihood of producing faulty products, minimizing rework and scrap, and enhancing overall production efficiency and customer satisfaction.

-

What are the benefits of implementing inline inspection?

Implementing inline inspection offers several benefits, including early defect detection, improved product quality, reduced production costs, increased operational efficiency, and enhanced customer satisfaction. By identifying and addressing issues in real-time, manufacturers can minimize waste, optimize production processes, and deliver products that meet or exceed customer expectations.

-

Can inline inspection be integrated with other quality control measures?

Yes, inline inspection can be integrated with other quality control measures to create a comprehensive quality assurance system. It can be combined with techniques such as statistical process control (SPC), automated data collection, and defect tracking systems to ensure seamless monitoring, analysis, and control of the production process for continuous quality improvement.

-

How does inline inspection contribute to process improvement?

Inline inspection contributes to process improvement by providing real-time feedback on the manufacturing process. By continuously monitoring product quality, manufacturers can identify areas for process optimization, make timely adjustments, and implement preventive measures to minimize defects and improve overall process efficiency and effectiveness.