Weight/Volume Control

& Average Quantity Law

Harford Weight Control Solutions uniquely combine the advantages of Average Quantity Law with Statistical Process Control and Process Capability, ensuring that optimal control can be achieved, whilst maintaining legality – even in processes with high levels of variation.

Weight Control Solutions

Whilst Average Quantity Law protects the consumer from purchasing underfilled product, when done well, it mainly benefits manufacturers by accepting the imperfect nature of production processes and thereby helps to reduce overfill and wastage.

A Brief History of Average Quantity Law

Average Quantity Law was introduced in August 1979 to replace the old Minimum Quantity system.

Minimum Quantity Law for pre-packaged goods was quite primitive, as it required all pre-packers to ensure that every pack contained at least the minimum quantity stated on the pack i.e. Minimum Quantity 1 Litre.

Given the natural variation which exists in all fast-moving production lines, it was considered fairer to allow manufacturers to split such variation between the packer and the consumer, whilst still committing to the pre-printed nominal quantities on the labels i.e. 1 litre. In this way, packers pay a little extra when they overfill and consumers lose a little through underfills, rather than packers paying the full cost of overfill.

So, Average Quantity Law was born. The Weights & Measures (Packaged Goods) Regulations 2006 is one of the few pieces of UK Government legislation that actually helps, rather than punishes FMCG manufacturers.

What is Average Quantity Law?

Average Quantity Law is a clearly defined legal requirement for the content control of most pre-packaged goods (packed and sealed before they reach the retailer) prescribed by weight and volume.

Average Quantity Law - The Rules:

There are three key rules which, at the time of production, a batch of packaged goods must comply with:

Rule 1 (Average): The actual contents of the packages must not be less, on average, than the nominal quantity (the weight or volume that is marked on the package or label)

Rule 2 (T1): The proportion of packages that are below the nominal quantity by a defined amount – the ‘tolerable negative error’ or TNE (T1) must be less than a specified level, in the UK and most of Europe, no more than 2.5% or 1 in 40 of the batch.

Rule 3 (T2): No package should be below the nominal quantity by more than twice the TNE (T2 level).

The Manufacturer’s Responsibilities

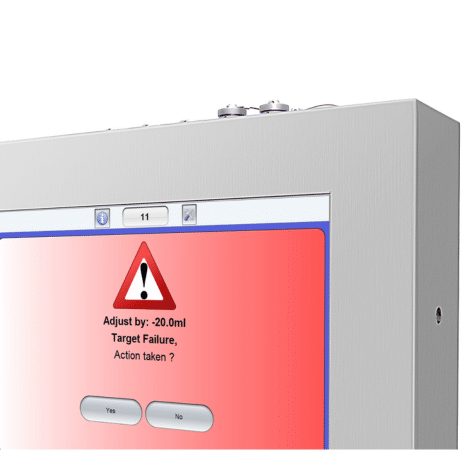

The manufacturer has a responsibility to ensure that they do not knowingly send out batches of product containing any T2 failures, more than 2.5% of T1 failures, and/or where the batch average is below the nominal quantity.

This is determined by statistical sampling throughout the production batch. (A batch is a clearly defined quantity which has been statistically checked by the manufacturer, has met the Three Packers’ Rules and for which a packer also has full documentation as a proof of due diligence if called upon to prove compliance by Trading Standards).

Harford’s Unique Average Quantity Control Algorithm

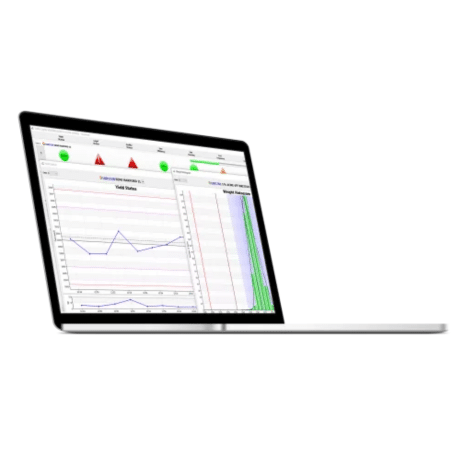

In contrast to our competitors, we adopted a unique and sustained approach by integrating the advantages of Average Quantity Control, Statistical Process Control (SPC), and Process Capability (Cp/Cpk). This combination enables us to achieve optimal control, even in situations where there are high levels of variation in the packing/bottling process.

Fewer Process Adjustments

When implemented correctly, Average Quantity Law is one of the few pieces of legislation that offers huge potential opportunities to reduce costs. The Harford system gives the operators clear adjustment instructions so they are making adjustments which keep the process in control and not by using guesswork.

Many sites using the Harford solution boast of overfill/giveaway levels as low as 0.1% (1ml per litre/1g per kg) – which they achieve by doing fewer process adjustments.

Any legal non-conformances are instantly flagged up and require approval, and all results and actions are fully traceable, for audits and trend analyses.

eMarking

The lower-case ‘e’ will often be seen on packages produced to the Average Quantity standard. This means that the product is definitely packed to Average Quantity Law, but even packages without the ‘e’ mark can be produced to the Average Quantity standard.

The additional benefit of e marking is the entitlement of free passage of the goods across EU member countries. To put this into context, if the goods were checked at the port of entry and found to be failing against the Average Quantity standard, if they are e marked, then they must be allowed to enter the country unhindered.

Average Weight Control Solutions for A Range of Industries

Weight control is crucial across various industries, including FMCG, Food & Beverage, Health & Beauty, Pharmaceutical and Chemical manufacturers. Accurate weight measurement and compliance with Average Quantity Law ensures product consistency, prevents underfilling, minimises overfilling and maintains consumer trust. By implementing Harford weight control solutions, manufacturers can eliminate risks, meet regulatory requirements and at the same time, minimise giveaway.

Wastage Control/Volume Control

Minimisation of overfill/underfill, reducing product waste

eMarking

Accurate and traceable weight verification for enhanced quality control

SPC

Real-time monitoring and analysis for consistent manufacturing quality

Machine Learning

Continuous improvement through data analysis and predictive insights

Average Quantity Law

Compliance with European standards for precise product quantities

Wastage Control/Volume Control

Minimisation of overfill/underfill, reducing product waste

Live Reporting and Analytics

Real-time data insights for proactive decision-making

Why Choose Harford Control for Average Quantity Control?

Our Weight/Volume Control programme was originally designed back in 1979, when European Average Quantity Law was first launched. It has constantly been developed and improved upon since then and still remains the market leader in terms of overfill reduction and legal compliance.

We took and sustained a different approach to all our competitors, in that we combined the benefits of Average Quantity Control with Statistical Process Control (SPC) and Process Capability (Cp / Cpk), ensuring that optimum control can be achieved even where high levels of variation exist in the packing/bottling process.

“Harford has supported us in reducing our bottling losses to less than 0.1%, and has taken our overall end to end liquid losses down by more than 50%. This alone has delivered sufficient savings back to the business to pay for Harford.”

— Plant Director, Loch Lomond Distillery

Who We Have Helped

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.