Vision Inspection

Harford Vision Inspection Solutions provide image-based inspection of a wide range of quality aspects with in-line cameras, ensuring that all products meet customer specifications.

Vision Inspection Systems – Safeguarding Product Integrity

If the packaging or the labels cannot be verified through the use of a barcode, 2D or QR code, e.g. due to artwork restrictions, it may be worth considering a vision inspection system.

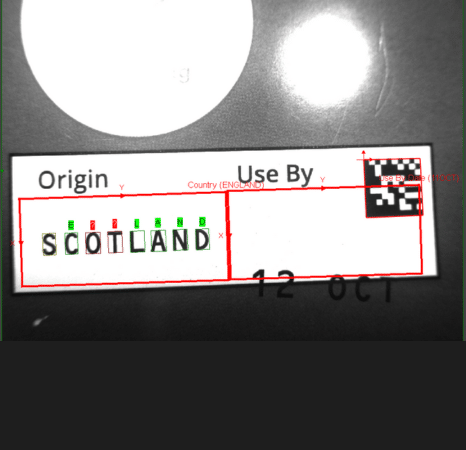

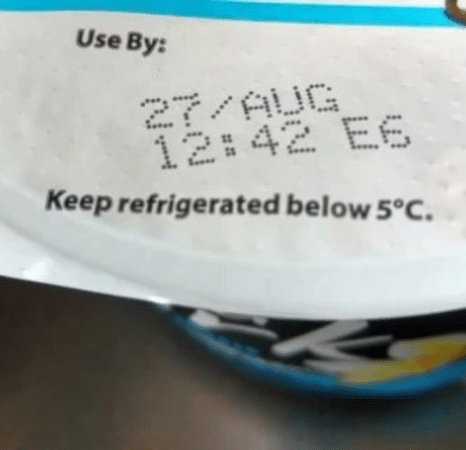

Automatic in-line vision inspection is becoming increasingly important for many FMCG, Food & Beverage, Health & Beauty, Pharmaceutical and Chemical manufacturers, especially for the growing need to ensure that products are allergen free and to ensure that date codes, product origin details, etc., printed on-line, are both legible and accurate. Image-based inspection with in-line cameras enables the comprehensive evaluation of various quality aspects, ensuring that all products meet customer specifications.

Enhancing Product Quality & Eliminating Defects

Harford Vision Inspection solutions offer a multitude of benefits to the manufacturing industries. With 100% inspection, defects are eliminated, production speed is increased, and customer specifications are consistently met. Our solutions ensure accurate component matching, enhancing product quality. They also improve process efficiency, minimise errors, reduce waste, and contribute to maintaining high standards, achieving compliance, and enhancing customer satisfaction.

Line Stop Functionality, Automatic Rejection Systems & Pattern Matching

Harford Vision Inspection solutions go beyond accurate label verification, accurate recognition of printed text, and 2D/QR code assessment. They include line stop functionality for consecutive failed packs and provide access to failed pack images in the inspection reports. With automatic rejection systems, pattern matching, and 100% inspection capabilities, our solutions ensure exceptionally consistent product quality, while swiftly identifying and addressing any defects.

Vision Inspection for FMCG, Food & Drink and Pharma Companies

Vision Inspection is critical in highly regulated industries such as FMCG, Food & Beverage, Health & Beauty, Pharmaceutical, and Chemical manufacturers to ensure product integrity, compliance and customer safety. Factories often rely on visual inspection solutions to discover faults, maintain consistent product quality, and fulfil industry standards in the face of rising quality demands and stringent regulations.

100% Inspection

Enable component matching and label verification without artwork redesign

OCR Front Recognition

Precise recognition of printed text on product/packaging surfaces

Machine Learning

Utilisation of advanced algorithms to improve inspection accuracy over time

2D/QR Code Inspection

Thorough assessment of 2D/QR codes to ensure readability and integrity

Pattern Matching

In-line camera captures product images, matches shapes using reference images

Vision Inspection Solutions – Why Work With Harford Control

Camera systems can play a vital role in ensuring product quality and compliance. Through our experience and partnership with Visicon, Harford Control combines our extensive independent capabilities and technical expertise, ensuring that we can deliver the highest quality solutions and service that both companies are renowned for.

Harford Control’s closer relationship with Visicon demonstrates our joint commitment to continuous improvement and our dedication to providing integrated solutions to customers worldwide.

Who We Have Helped

FAQs

-

What is vision inspection in manufacturing?

Vision inspection is a technology-driven process that uses cameras, sensors, and image processing algorithms to perform automated visual inspections of products during the manufacturing process. It can detect defects, measure dimensions, identify missing components, and verify product quality based on predefined criteria. Vision inspection systems provide fast, accurate, and reliable inspection results.

-

Why is vision inspection important in manufacturing?

Vision inspection plays a crucial role in manufacturing by ensuring product quality, consistency, and compliance with specifications. It can detect even subtle defects and variations that may be difficult to identify with the human eye. Vision inspection systems enhance production efficiency, reduce manual inspection errors, and help manufacturers maintain high-quality standards.

-

What are the benefits of implementing vision inspection?

Implementing vision inspection offers numerous benefits, including improved product quality, increased inspection speed, reduced labour costs, enhanced process efficiency, and minimized product recalls. Vision inspection systems provide reliable and objective inspection results, enabling manufacturers to achieve higher levels of accuracy, productivity, and customer satisfaction.

-

What types of defects can vision inspection detect?

Vision inspection systems can detect various types of defects, including surface flaws, scratches, cracks, colour variations, misalignments, missing components, and incorrect labelling. The systems use advanced image processing algorithms to analyse captured images and compare them with reference standards to identify any deviations or anomalies that may indicate defects.

-

How does vision inspection contribute to process improvement?

Vision inspection contributes to process improvement by providing real-time feedback on product quality and production processes. It helps identify trends, patterns, and areas for improvement, enabling manufacturers to optimize their manufacturing processes, reduce defects, minimize waste, and enhance overall process efficiency and effectiveness.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.