Editorials

Digital Transformation – Computer Systems Alone Cannot Drive Change

Drive Cost-Effective Improvement and See Profits Increase: Part Two

In part one, we discussed the need for Digital Transformation in that its primary function is not to remove ‘paper’ from the manufacturing process, though that would be a desirable soft benefit, but to minimise risks and to highlight ‘actions’ in real-time, to reduce risks, minimise waste and optimise production efficiency. These hard (more quantifiable) benefits would ultimately enable the manufacture of products to be:

safer, better, faster and cheaper.

For decades, manufacturers have attempted to digitise their processes to improve operational discipline and gain instant, high visibility of production status, in order to take appropriate actions and thereby see immediate improvements. According to independent experts, this has not always gone well, with over 70% of factory floor digitisation projects, failing to meet objectives.

70% Failure Rate in Digital Transformation

With such a high failure rate, it is hardly surprising that many companies, desperate to improve, are nevertheless reluctant to risk the investment and, therefore, choose to remain with what they know. When it was possible to build a few percent into the costings to cover mistakes, wastage and inefficiencies, paper recording, for all its weaknesses, was bearable. Nobody would deny that so much has changed since those ‘halcyon’ days of long batch runs, few product variables and that built-in error margin.

With such a high failure rate, it is hardly surprising that many companies, desperate to improve, are nevertheless reluctant to risk the investment and, therefore, choose to remain with what they know. When it was possible to build a few percent into the costings to cover mistakes, wastage and inefficiencies, paper recording, for all its weaknesses, was bearable. Nobody would deny that so much has changed since those ‘halcyon’ days of long batch runs, few product variables and that built-in error margin.

Increased Costs/Reduced Selling Prices

A number of factors have forced a change in behaviour. Even at the start of the last decade, some companies told us they had already moved on from building in a bit of ‘fat’ to ‘every pound is a prisoner’. It is now becoming increasingly common to hear manufacturers say ‘every penny is a prisoner’. This change has largely been forced upon manufacturers by increased competition between supermarkets on the one hand and rising input costs on the other, in the form of increased salaries, pension contributions, raw materials, energy costs, etc.

“Every penny is a prisoner.”

Due to the increased competition, when manufacturers do ask supermarkets to accept a price increase, they are often either turned down completely, or asked to prove what they have done to reduce their own transformation costs.

This is, as many have already found, far more difficult than it sounds and can certainly not be resolved through the installation of a cheap digital system and the removal of paperwork. That may be a step in the right direction, so long as the right digital system is chosen, but it does not go nearly far enough.

No Substitute for a Lean Culture

Concurrent with the installation of the system, or even beforehand, the most successful implementations happen where companies have set about creating a Lean culture, to minimise wastage, improve quality consistency and reduce risk at every opportunity.

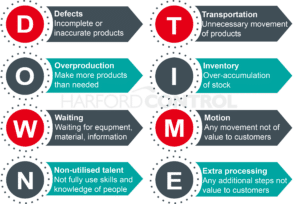

This will often start with a 5S programme (basically a place for everything and everything in its place), followed by an understanding of the main 8 categories of waste to be eliminated. These form the convenient mnemonic DOWNTIME, ‘The 8 Deadly Lean Wastes’:

Once this is understood and embedded as the beginnings of Lean culture, companies can begin in earnest to appoint Lean champions to drive Continuous Improvement through Value Stream Mapping, Kaizen bursts and DMAIC, etc. Although there is far more to Lean, a well-communicated understanding of these few basics, together with a well-trained and motivated workforce, can achieve a great deal and encourage further improvement.

The Right Digital System is Paramount

However, once this Lean culture is firmly embedded, then the choice of the right digital system is essential to eliminate paper recording, improve operational discipline, minimise errors and instantly increase communication, both across the factory floor and to the top floor, in real-time.

In this way, everyone knows the current production status and, from the manner in which the information is presented by the system, are enabled to take instant improvement actions, without any further data conversion or data manipulation.

Some sites, already enjoying the benefits from such systems being firmly embedded, have developed their own Lean cultures, sufficient to see improvements as high as the complete elimination of defects, overproduction and unnecessary wastage, whilst efficiencies have increased by as much as 20% of turnover.

Small Profit Margins

These effectively rolled out improvements have become far more than a wish-list. Even before the more recent challenges mentioned above, which are constantly increasing, the UK food and drink industry was operating on tiny profit margins.

These effectively rolled out improvements have become far more than a wish-list. Even before the more recent challenges mentioned above, which are constantly increasing, the UK food and drink industry was operating on tiny profit margins.

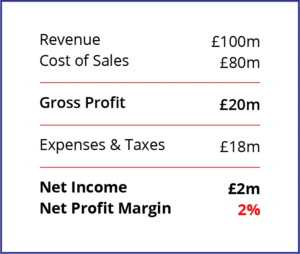

When viewing company accounts, it is not unusual to see turnovers in the region of £100 million, with the cost of sales as high as £80 million. In strict accounting terms, the Cost of Sales should only include the raw materials, wastage and the direct conversion costs from raw materials to finished goods. In such a scenario, this leaves only £20 million to cover all the other expenses. It would, therefore, not be unusual to see this gross profit difference of £20 million reduced to a net profit before tax of £2 million (2% of turnover). Some accounts we have seen have shown a net profit percentage of even less.

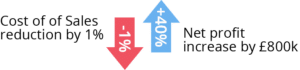

Given the above example, a mere 1% saving, amongst The 8 Deadly Lean Wastes, would add £800,000 to the net profit, (an increase of 40%). It is always best to attack the manufacturing transformation costs first, as these will invariably show the biggest rewards.

For more details or pro bono consultancy, contact our experts.

Share your thoughts to Info@harfordcontrol.com or give us a call on +44 (0) 1225 764461