Editorials

Does your Continuous Improvement Plan for the Coming Year have 2020 Vision?

You might be very clear on what you want to achieve during the coming year, but do you have total visibility of production operations, in real-time? You might personally be blessed with 20:20 vision, but unless you can see precisely what is happening right now, within your production operations, then it is hard to see how you can expect to achieve your objectives.

The well-worn phrase ‘You cannot improve what you don’t measure’ could also include ‘You can’t improve what you can’t see’

Real-time visibility of factory floor operations has now become an essential performance improvement vehicle on the road to Operational Excellence.

Management of Change

The ‘old chestnut’ about the Three States of Management:

‘What Management Would Like to be Happening,

What Management Think is happening, and

What is Actually Happening’

could now be confined to ‘the dustbin of history’ as real-time cross-functional factory floor performance gives the whole operational team what they have wanted for years, ‘One and only one accurate and instant version of the truth, from shop floor to top floor’. Potential threats are too great to ignore and there is no substitute for real-time, analysed, prioritised and distributed information, such that operational personnel can confidently take the corrective actions which will bring about quantifiable and sustainable improvements.

With the world changing at such a phenomenal rate, it is difficult for any of us to keep pace. Some have already given up. As has often been said, change is not mandatory. Against this backdrop of never-ending change, companies can decide to stay as they are, with a well-rehearsed mantra ‘if it ain’t broke why try to fix it’ until the day comes when the shutters come down, the day when their luck finally runs out and their world changes forever. Who amongst us could have imagined that such famous and long-standing names as Thomas Cook, Mothercare and Maplins would be no more?

When I travel around the UK talking to food manufacturers, I find very mixed attitudes to Change. Some, such as Diageo (the biggest alcoholic drinks producer in the world, with such famous brands as Guinness, Johnnie Walker, Smirnoff and Baileys, to mention just a few) are very progressive and totally focussed upon the creation of consistently high-quality products at lowest manufactured cost. By so doing, they place themselves in the best possible position to meet whatever challenges the future brings.

One large vegetable packer told me that they had the same volume of business from all their supermarket customers this year as they had last year, but at lower prices!

With increased raw material costs, annual increases in the minimum/living wage and pension contributions, together with lower prices from their customers, why isn’t every company looking inwardly to see what they can change to minimise risk and enhance profitability?

Yet, the most frequent comment we hear when we ask about change or performance improvement objectives is ‘Oh! It’s just too early yet’ leaving us tempted to ask ‘How will you know when it’s too late?’

Beneficial Change must become the New Normal, rather than the Exception

We haven’t been in many companies that could not benefit from an increased commitment to improvement objectives. We have yet to meet the perfect company that has achieved performance optimisation, i.e. consistently high quality, minimal possible waste, maximum possible efficiency and zero carbon emissions.

Why? From the foregoing, we already know why companies determined to stay around for the long term must accept continuous change as the new normal.

How? Many companies have tried to make improvements to existing performance through the use of Excel Spreadsheets and/or SAP, or some other existing system. Such initiatives, whilst commendable, only take you so far and do not seriously begin to compare with the instant visibility and analysis from dedicated management information and execution systems.

Companies committed to generating real-time actionable information, and the elimination of paper recording, to drive their performance improvement initiatives, will already recognise many of the benefits in going to a specialist company with a truly consultative approach to performance improvement. Such companies, to provide maximum value, will need to do more than simply supply a well-developed computer system. They will also need to have demonstrated that they have a very clear understanding of the dynamics required to drive continuous improvement, such as those available from exponents of Lean Six Sigma.

Our sales consultants consistently use their Lean Six Sigma Black Belt training to help companies improve and, in so doing, clearly demonstrate that the gaining of such skills was 100% customer focussed.

What and Where? Every part of the manufacturing process, from goods inwards to despatch, should be candidates for performance improvement. Much of the data can be collected automatically from existing legacy equipment, such as filling machines and in-line checkweighers, but also the automated set-up of date coders and on-line barcode scanners can minimise production risk and eliminate label compliance-related batch rejections. Such data collection can be further complemented by quality stations strategically placed for operator utilisation, together with the use of computer tablets as a ‘mopping up’ operation for roving quality audits, quality assurance, Health & Safety checks, CCPs and so on, creating a truly paperless and real-time production environment.

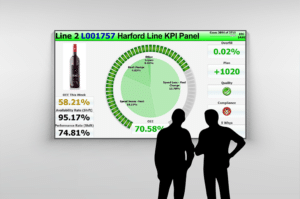

Large factory screens turn this real-time data into valuable information which can be seen by everybody and which is instantly actionable. Whilst such systems do not in themselves make the performance adjustments necessary to guarantee improvement, they provide consistent and instant awareness of issues and performance improvement opportunities, making the taking of improvement actions both easy and obvious.

Large factory screens turn this real-time data into valuable information which can be seen by everybody and which is instantly actionable. Whilst such systems do not in themselves make the performance adjustments necessary to guarantee improvement, they provide consistent and instant awareness of issues and performance improvement opportunities, making the taking of improvement actions both easy and obvious.

When? Ideally yesterday! There is no time to lose.

Share your thoughts to Info@harfordcontrol.com or give us a call on +44 (0) 1225 764461