Traceability

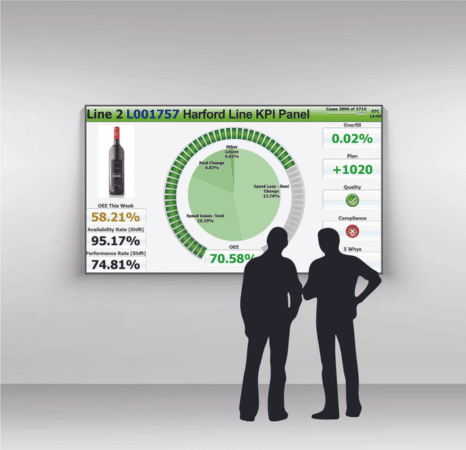

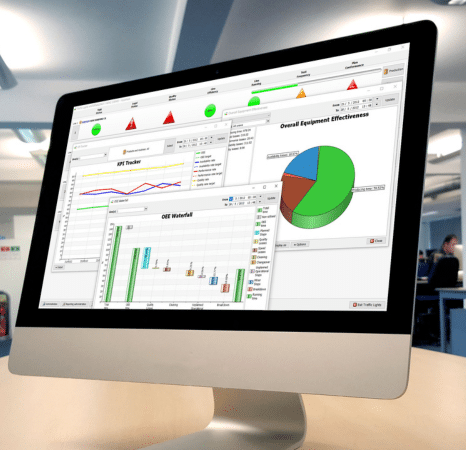

Harford Traceability Solutions offer manufacturers precise, real-time data reporting. Harford’s information is measured, analysed and instantly displayed through user-friendly screens accessible from the shop floor to the top floor, facilitating data-driven decision-making.

End-to-End Traceability Solutions for Manufacturing Companies

We provide accurate real-time reporting for FMCG, Food & Beverage, Heath & Beauty, Pharmaceutical and Chemical manufacturers.

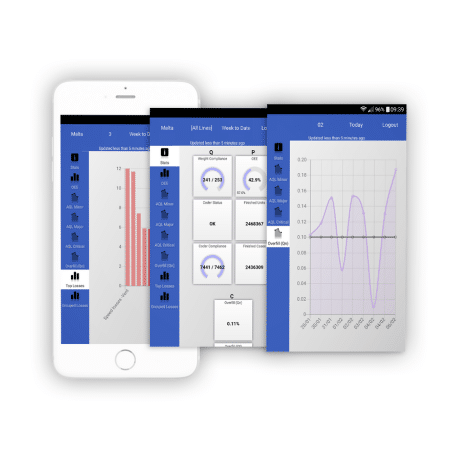

All Harford’s information is measured, analysed and displayed, in real time, through easily understood screens available from the shop floor to the top floor, enabling instant rectification of problems or improvement actions, to sustain and improve performance. Such valuable real-time information is also available remotely via tablets and mobile phones.

This instant visibility puts your team firmly in control and leaves them in no doubt as to the most effective actions to take and when to take them.

Manufacturing Traceability Solutions

All the real-time information is displayed across integrated networks and large TV screens in the production area, enabling you to track and trace every aspect of your production processes, from raw materials to finished products.

With Pareto analysis, DMAIC, 5 Whys, and Fishbone Diagrams incorporated into our Traffic Light reports, we provide the granularity that you need to drill down to the root cause of downtime problems. Managers and operators can take action immediately based on real-time actionable information, without guesswork.

Inventory Optimisation and Control

Streamline your inventory management process with accuracy and efficiency, ensuring optimal stock levels and enhanced control over your supply chain. Experience seamless inventory operations and achieve operational excellence through full integration with ERP/Stock Control Systems.

Knowing how much stock is needed to fulfill orders and not overproducing simply to fill a space in the warehouse. The Harford solution helps to minimise waste by only producing what is needed to fulfill orders. The provision of real time production data helps to prevent overproduction.

Typical Customer Feedback

“We now have the added benefit of seeing real-time performance data, that is beginning to yield greater efficiencies on our production lines, as a result of our ability to identify and tackle the biggest causes of downtime.” — Plant Director, Loch Lomond Distillers

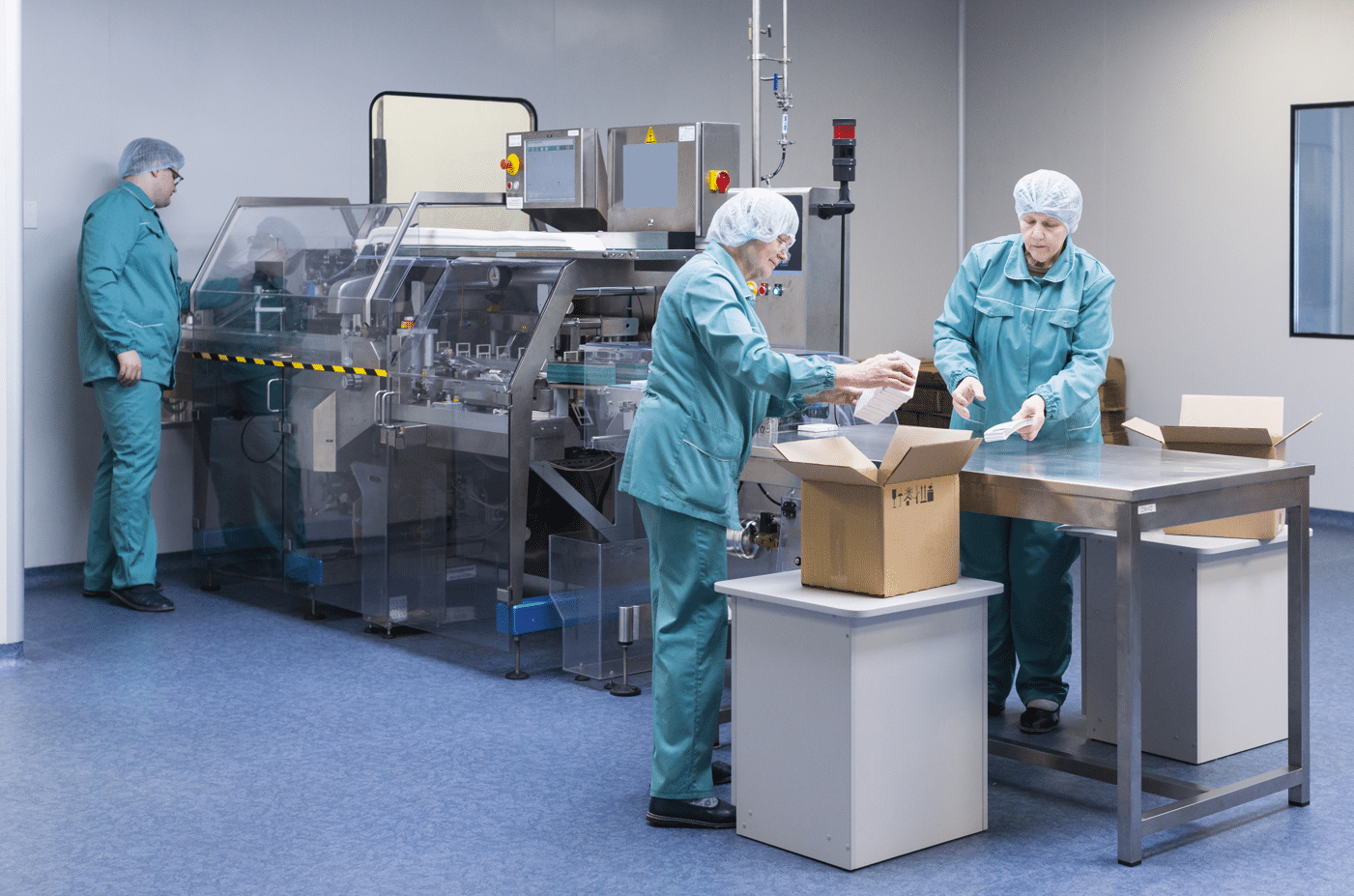

Full Traceability to Include Pharmaceutical Industries

Our tailored solution for the pharmaceutical manufacturing sector are no less important than those for other industry sectors such as food and beverage, household chemical, cosmetics and toiletries, etc., thus ensuring complete traceability across all industry sectors including pharmaceutical serialisation.

We therefore deliver real-time information and traceability across networks, PCs, large TV screens, tablets and mobile phones, enabling comprehensive tracking and tracing of all production processes. With such advanced traceability, we provide the necessary granularity to identify the root cause of any downtime issues. This empowers pharmaceutical managers and operators to quickly act upon real-time insights, eliminating guesswork and fostering more streamlined operation.

Real-time Track & Trace

Monitor the flow of materials, components and finished products

Comprehensive Data Integration

Seamless integration of data from various sources

Granular Visibility & Control

Track and monitor every step for compliance and quality control

Batch & Material Tracking

Trace specific products or components back to their origins

Analytics & Reporting

Analyse data, identify patterns and generate reports for process optimisation

Why Work with Harford Control?

Over several decades, Harford Control has worked tirelessly with a wide range of factories across five continents to help optimise their production performance.

With the Harford Manufacturing Execution System (MES) tailored to individual needs, it becomes easier to reduce errors, find the hidden wastage and consequently become more efficient, whilst continuing to deliver consistently high quality products, thereby making each business more profitable and sustainable.

Most manufacturers are facing ever increasing input and transformation costs with few opportunities to increase the output price to their customers (High Street Multiples).

This encourages manufacturers to look more deeply into their production processes to find the hidden costs, eliminate wastage and thereby improve efficiency without compromising quality.

The problem of rising input costs and fixed output costs is nothing new and will not end. Therefore performance improvement to drive down transformation costs must be continuous for the business to sustain its market position and avoid losing its place on supermarket shelves to the competition.

Who We Have Helped

FAQs

-

What is traceability in manufacturing?

Traceability in manufacturing refers to the ability to track and trace the safe movement of high quality products and their components throughout the supply chain. It involves capturing and recording information about the origin, production process, and distribution of products, enabling manufacturers to identify and trace specific items, ensuring quality control, and facilitating early product recalls, if critical failures are identified.

-

Can traceability be applied in multiple industries?

Yes, traceability is applicable across any industries, including food and beverages, pharmaceuticals, automotive, electronics, and more. Each industry has specific requirements and regulations related to product quality traceability. Implementing traceability systems tailored to industry standards and needs enables manufacturers to meet regulatory requirements, enhance product quality, and ensure consumer safety and satisfaction.

-

How does traceability benefit manufacturers?

Traceability benefits manufacturers by providing visibility and control across their supply chain. It helps prevent and mitigate the impact of quality issues, reduces the risk of product recalls, and enables efficient investigation and resolution of product-related incidents. Traceability also supports compliance with industry regulations and standards, strengthens and protects brand reputation, and improves customer satisfaction and safety. Allergen control and traceability is a good example.

-

Can traceability help in product recalls?

Yes, traceability plays a crucial role in product recalls. In the event of a product recall, traceability enables manufacturers to quickly identify affected items, trace their distribution, and locate the root cause of any issues. This facilitates targeted recalls, minimizes the impact on consumers, and ensures timely actions to address the problem, protecting both public safety and the manufacturer’s reputation, with evidential proof of ‘due diligence’.

Get in touch

"*" indicates required fields

Telephone

+44 (0) 1225 764461Harford Control Ltd is a company registered in England with Company Number 1207483. VAT No. GB 140 2121 39.