Editorials

Digital Transformation in F&D manufacturing

A recent survey commissioned by IBM, covering all manufacturing, was very informative, as you might expect from such a high-profile company.

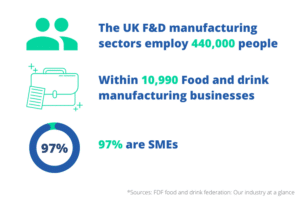

As I am mainly concerned with the Food and Drink Industry, this is my focus in reading their broad analysis. It surprised me that a mere 2% of those contributing to the survey were from Food and Drink Manufacturing. However, ‘food and drink’ is the largest of the UK manufacturing sectors, employing 440,000 people, within 10,990 food and drink manufacturing businesses, 97% of which are SMEs.

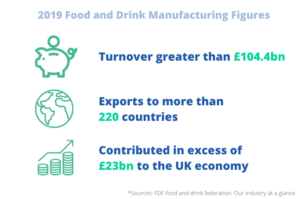

In 2019, this industry had a turnover greater than £104.4bn and accounted for nearly 20% of all UK manufacturing. In 2019, exports of food and drink to more than 220 countries contributed in excess of £23bn to the UK economy.

So why, with such a huge contribution to UK manufacturing, did food and drink constitute only 2% of this important survey?

Survey ‘population’

This apparently ‘low turnout’ could be due to the survey ‘population’. We all know that poll predictions taken pre-elections can give very misleading results, dependent upon the sampling location and distribution. A poll compiled from questions posed to visitors to a top-level UK supermarket, might give a completely different ‘skew’ to one posed to visitors to a ‘discounter’, as we all know that the demographics, taken from where people shop, could be a fair indicator as to how they might vote. Results taken from a top university might again give a completely different result. All may create a certain view, but most will be an inaccurate indication, as the sample taken for the poll was not representative.

We don’t know how this particular survey was carried out. All we do know is that only 2% of contributors were from food and drink manufacturing.

Priority: staying in business

Perhaps the sample was a very fair representation, but it happened to be taken at a time when the UK food and drink industry had other priorities. This might not be an unreasonable assumption as it was taken last November/December, when the food and drink industry were desperately trying to cope with the consequences of Covid 19 and still reeling from ‘Brexit’, now its true consequences, rather than political rhetoric, are becoming more apparent. For many, the biggest priority could merely have been ‘staying in business’ through such turbulent times, rather than answering a survey about ‘Digital Transformation’.

The survey mirrored our own experiences: in common, we have found comments like these; ‘The Covid pandemic has shown up several weaknesses and our priority above all else is to deal with these effectively.’ ‘Achieving maximum production efficiency whilst minimising waste has become our key goal.’ ‘In a business where ‘every penny is a prisoner’, long term goals have fallen way down our list of priorities in favour of short term cash based imperatives’.

Sales volumes struggle to recover

Other concerns also threaten sales volumes for the food and drink sector, already struggling to recover. According to one prediction, marketing restrictions could cost the food and drink sector worldwide, circa £500 billion per year. According to The British Heart Foundation, around 31,000 heart and circulatory deaths each year are attributed to obesity. A number of leading organisations are calling for restrictions to curb the sale of high sugar, salt and fat foods, similar, in part, to the restrictions placed upon tobacco advertising. By comparison, in 2003, when the restrictions on tobacco advertising were introduced, 26% of UK residents smoked, but by 2019 that figure had fallen to 14%.

Digital transformation plays a key role

So, back to Digital Transformation. Despite the low poll in the survey, is it a good idea for the food and drink sector? What benefits does it provide?

We would say that, for the manufacture of fast-moving consumer goods, sometimes manufactured at speeds of 800 packs per minute, there is no viable alternative other than to make the consequences of all manufacturing operations instantly visible. Not just by displaying the data, but by turning data into instantly actionable information. Most companies already have masses of data, often manually collected, some digitally, even in real-time, but it isn’t actionable without more work. Consequently, quality and/or efficiency problems often remain unaddressed for long periods, leading to quarantine, rework, wastage, product recalls, batch rejections and even lost contracts.

The biggest priorities facing food and drink producers, other than concerns already mentioned are:

- Allergen Control,

- Compliance

- Quality Consistency

- Efficiency

- Wastage

Some of these can impact product safety and any of these can, and often do, adversely affect company profit margins.

In FMCG operations we see Digital Transformation as essential for companies determined to consistently deliver safe, quality products, improve efficiencies, drive out wastage and improve overall operational effectiveness, but with money in short supply, it must be done cost effectively. It must be done not merely to digitise manual data, but to drive improvement actions and it must be justified from the savings to be made, rather than just adding further cost to the business.

“Digital Transformation as essential for companies determined to consistently deliver safe, quality products, improve efficiencies, drive out wastage and improve overall operational effectiveness, but with money in short supply, it must be done cost effectively.”

Some client comments, which we have heard many times, may resonate:

“We still spend more time making the report than doing something with it.”

“We’ve picked all the low hanging fruit. Digitalisation is helping us uncover missed and new efficiency improvements.”

One client said to us a few years ago:

“Our in-house efficiency system is great for seeing the top-level performance, but lacks granularity and the necessary drill down, to attack and fix root cause. Last year we lost 4-million-man minutes and don’t know where.”

If any of the above resonates with yourselves, call us any time.

Roy Green, Harford Control Ltd.

Share your thoughts to Info@harfordcontrol.com or give us a call on +44 (0) 1225 764461