Editorials

Spirit of The Open

Loch Lomond Distillers – from Little(mill) beginnings to sponsoring The Open Golf Championship

In recent years, many whisky bottlers have shifted their emphasis from blended whiskys in favour of malts, preferably aged single malts. During the past few weeks, a new record was created when two bottles of Macallan sold at auction in Dubai for a whopping $1.2 million. This product was distilled in 1926 and aged for 60 years in sherry casks before being bottled. The labels were designed by artist Sir Peter Blake who also designed the Beatles’ Sergeant Pepper album sleeve. With each bottle costing a massive £430,000 they are clearly collector’s items, but anyone wealthy enough to drink them would be £15,000 the poorer per nip.

Exceptions aside, the move in whisky is most definitely towards the luxury end of the market. The larger companies such as Diageo, Beam Suntory, Edrington (Macallan, etc), William Grant, et al; are clearly placing greater emphasis upon the luxury product market.

Loch Lomond Distillers

But this is by no means the exclusive domain of the larger manufacturers. A smaller and lesser known company, Loch Lomond Distillers, is increasing in popularity for its high-end products. LLD is probably better known for its production of Glen Vodka, which we are told is currently the biggest selling vodka brand in Scotland.

However, during the past 4 years, LLD’s product base has increased from 150 SKUs to 850. This huge increase in its product portfolio has been largely due to LLD’s focus upon single malts, single cask bottling and, of course, label changes as, during this same period, the company has expanded its sales from 10 markets to 120, across six continents and at the same time increased its international sales by more than ten-fold.

Obviously, the maturation and storage of products for longer periods hugely increases their value so that, by the time they are bottled, the reduction in product giveaway becomes even more important.

To help address such a huge transformation and increase in complexity, whilst at the same time, maintaining high levels of quality and efficiency, LLD installed a Harford factory floor information management system. So far, this has helped them to reduce spirit losses due to overfill and virtually eliminate paper from the factory floor. It has also improved traceability and dramatically increased the visibility of real-time performance of each production line, making any compliance, quality, overfill, inefficiency or other forms of wastage, instantly visible to the whole operational and management teams.

A Brief History of Loch Lomond Distillers

There was a Loch Lomond Distillery first established in Arrochar as early as 1814, which closed 3 years later. The present Loch Lomond Distillery was established in 1964 by the former owners of the Littlemill Distillery in Bowling. Littlemill itself dates back to 1750 and is claimed to be the oldest distillery in Scotland.

It deployed a number of groundbreaking techniques to gain greater control over the distillation process. Following a succession of owners and temporary closures, it finally closed in 1989 and was sold to Loch Lomond Distillery. It was largely dismantled in 1997 and the remnants were destroyed by fire in 2004.

The former owner of Littlemill, Duncan Barton, developed the current site for the Loch Lomond Distillery. He bought innovative pot malt stills which rest in the cylindrical necks of the spirit stills. The necks of traditional malt stills are open. The Loch Lomond stills include special distillation trays which are said to make the process more efficient. This type of still, in addition to producing higher alcohol strengths, is also said to allow for different ‘flavour notes’ to be captured. This is apparently more difficult to achieve through conventional pot stills.

In 2014, the Loch Lomond Group was acquired by the private equity group, Exponent. In 2016, more new stills were installed, allowing grain whisky, single malt whisky, single grain whisky and blended whisky to all be made on the same premises.

Back to the Present

Loch Lomond’s bottling plant at Glen Catrine in Ayrshire was bottling more than 65 million bottles of whisky and other spirits per year, back in 2016.

At that time, the company had already started to grow its product portfolio towards the 850 SKUs mentioned above and to expand its sales from the 10 markets to its 120 market exposure today.

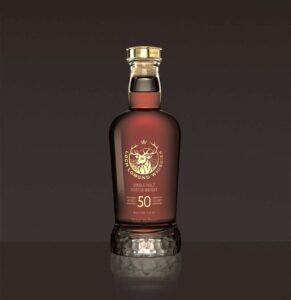

Last year, LLD launched its Loch Lomond 50-year-old single malt which sells for around £12,000 per bottle.

As Tony Brewerton, Plant Director, said, “Such a rapid increase in complexity and global market growth over a four year period, creates many new challenges and risks. To help us address these we turned to Harford Control with its well-established factory floor information management system.”

Asked how the Harford System had helped, Tony Brewerton made this comment:

“Producing a great quality product, at best cost, is continuing to be a challenge for everyone in the manufacturing industry, and the drinks business is no exception. Where shelf price is increasingly sensitive, cost control continues to be challenging due to changes to employee pensions and national living wage, plus the fluctuations in the value of the pound impacting our supply chain. We have looked at every line of our accounts to seek ways in which we can reduce our overheads and waste. Our liquid is the most valuable material used in our conversion process, and reducing losses in liquid processing and bottling was a way in which we identified that we could take out cost. Before we implemented the Harford system, an analysis showed us that we were overfilling bottles by around 0.75%, which doesn’t sound a lot, however, when producing at 250-300 bottles per minute, the cost very quickly adds up, especially with more valuable aged malts. One year after implementation and Harford has supported us in reducing our bottling losses to less than 0.1 %, and has taken our overall end to end liquid losses down by more than 50%. This alone has delivered sufficient savings back to the business to pay for Harford. Plus, we now have the added benefit of seeing real-time performance data, that is beginning to yield greater efficiencies on our production lines, as a result of our ability to identify and tackle the biggest causes of downtime.”

Tony Brewerton, Plant Director, Loch Lomond Distillers

To further reduce paper recording, improve control and increase real-time visibility, within the factory, LLD have also recently installed a warehouse management system from Indigo, which already has a history with a number of companies, including Greene King and Dairy Crest. Once existing systems have bedded in, we have no doubt that Harford will be asked to link with Indigo to further reduce paper.

This year Loch Lomond Distillers are sponsoring The Open Golf Championships, being held at Carnoustie between 15th and 22nd July, to provide even greater exposure and recognition of their quality products.

We look forward to continuing to support Loch Lomond Distillers’ on-going transformation and expansion and to a long, mutually beneficial relationship.

Find out more about Harford factory floor information management system.

Roy Green, Harford Control Ltd.

Share your thoughts to Info@harfordcontrol.com or give us a call on +44 (0) 1225 764461